Teburin Abubuwan Ciki

- 1. Bayanin Samfur

- 1.1 Fa'idodi na Ciki da Kasuwar Da Ake Nufi

- 2. Bincike Mai Zurfi na Ma'auni na Fasaha

- 2.1 Iyakar Ƙididdiga Cikakke

- 2.2 Halayen Lantarki da Haske

- 3. Bayanin Tsarin Rarrabawa (Binning)

- 3.1 Rarrabawar Ƙarfin Hasken (Luminous Intensity)

- 3.2 Rarrabawar Tsawon Zangon Haske (Dominant Wavelength)

- 3.3 Rarrabawar Ƙarfin Wutar Gaba (Forward Voltage)

- 4. Binciken Lanƙwan Ayyuka

- 4.1 Matsakaicin Hasken Dangane da Yanayin Zafi

- 4.2 Ƙarfin Wutar Gaba Dangane da Ƙarfin Wuta (Lanƙwan I-V)

- 4.3 Matsakaicin Hasken Dangane da Ƙarfin Wutar Gaba

- 4.4 Tsarin Watsa Hasken da Rarraba Bakan Haske

- 5. Bayanan Injiniya da Kunshi

- 6. Jagororin Solder da Haɗawa

- 7. Bayanan Kunshi da Oda

- 8. Shawarwarin Aikace-aikace

- 8.1 Yanayin Aikace-aikace na Yau da Kullun

- 8.2 Abubuwan Da Ake Bukatar Yi La'akari Da Su A Zance

- 9. Aminci da Tabbatar da Inganci

- 10. Kwatancen Fasaha da Bambance-bambance

- 11. Tambayoyin Da Ake Yawan Yi (FAQs)

- 12. Misalan Zance da Amfani na Aiki

- 13. Ka'idar Aiki

- 14. Trends na Masana'antu da Mahallin

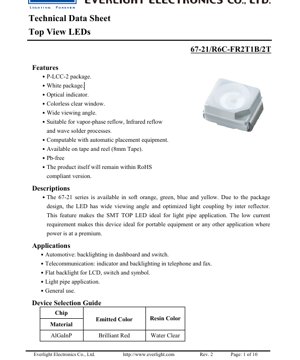

1. Bayanin Samfur Jerin 67-21 suna wakiltar dangin LED na Surface-Mount Top View waɗanda aka ƙera don aikace-aikacen nuna alama da hasken baya. Wannan ƙirar ta musamman tana da launin watsa haske ja mai haske wanda aka samu ta hanyar fasahar guntu na AlGaInP. Na'urar tana cikin ƙaramin kunshin P-LCC-2 mai farar jiki da taga mai tsafta mara launi, wanda ke taimakawa wajen halayen sa na faɗin kallo. Wani muhimmin siffa na ƙira shine haɗakar mai juyawa a cikin kunshin, wanda ke inganta ingancin haɗakar haske. Wannan ya sa LED ta dace musamman don amfani da bututun haske, inda ingantaccen watsa haske daga tushe zuwa wurin nuni yake da mahimmanci. Ƙarancin buƙatun wutar lantarki yana ƙara dacewarsa don aikace-aikacen masu hankali ga wutar lantarki kamar na'urorin lantarki masu ɗauka da allunan motoci.

1.1 Fa'idodi na Ciki da Kasuwar Da Ake Nufi Babban fa'idodin wannan jerin LED sun haɗa da faɗin kallon sa na digiri 120, dacewa da daidaitattun hanyoyin sanyawa da solder na atomatik (ciki har da vapor-phase, infrared reflow, da wave soldering), da kuma ginin sa mara gubar, mai bin ka'idodin RoHS. Ana ba da na'urar akan kaset ɗin tef 8mm da reel don haɗawa mai yawa. Kasuwowar da ake nufi da farko sune na'urorin lantarki na mota (don allunan nuni da hasken baya na maɓalli), kayan aikin sadarwa (don alamomi a cikin wayoyi da na'urorin faks), hasken maɓalli da alamomi gabaɗaya, da kuma azaman tushen hasken baya mai lebur na LCDs. Haɗin aminci, sauƙin haɗawa, da aikin gani sun sanya shi a matsayin kayan aiki mai fa'ida don amfanin nuna alama na gabaɗaya.

2. Bincike Mai Zurfi na Ma'auni na Fasaha Aikin LED ana bayyana shi a ƙarƙashin daidaitattun yanayin gwaji na yanayin zafi (Ta) na 25°C. Cikakkiyar fahimtar waɗannan ma'auni yana da mahimmanci don ƙirar da'ira daidai da hasashen aiki.

2.1 Iyakar Ƙididdiga Cikakke Waɗannan ƙididdiga suna bayyana iyakokin damuwa waɗanda sama da su lalacewa na dindindin na iya faruwa ga na'urar. Ba a ba da garantin aiki a ƙarƙashin ko a waɗannan iyakokin ba. Manyan iyakar ƙididdiga cikakke sune: ƙarfin wutar baya (V_R) na 5V, ci gaba da ƙarfin wutar gaba (I_F) na 25mA, da ƙarfin ƙarfin wutar gaba (I_FP) na 100mA don aikin bugun jini a cikin zagayowar aiki 1/10 da mitar 1kHz. Matsakaicin raguwar wutar lantarki (P_TOT) shine 100mW. Na'urar na iya aiki a cikin kewayon zafin jiki daga -40°C zuwa +85°C kuma ana iya adana ta tsakanin -40°C da +90°C. Yanayin zafin solder yana da mahimmanci: don sake kunnawa solder, an ƙayyade matsakaicin zafin jiki na 260°C na matsakaicin dakika 10, yayin da don solder da hannu, zafin ƙarshen ƙarfe bai kamata ya wuce 350°C ba na dakika 3.

2.2 Halayen Lantarki da Haske Matsakaicin wurin aiki na ƙayyadaddun ƙididdiga na photometric da na lantarki yana a ƙarfin wutar gaba na 20mA. Ƙarfin haske (I_V) yana da kewayon yau da kullun daga 140mcd zuwa 360mcd, wanda aka ƙara raba shi zuwa takamaiman kwandon shara (R2, S1, S2, T1). Tsawon zangon haske (λ_D) na bambancin ja mai haske yana tsakanin 621nm da 631nm, tare da matsakaicin tsawon zango (λ_P) a kusa da 632nm. Faɗin bakan haske (Δλ) yana kusan 20nm. A lantarki, ƙarfin wutar gaba (V_F) a 20mA ya bambanta daga 1.75V zuwa 2.35V, kuma ƙarfin wutar baya (I_R) an ba da garantin zai kasance ƙasa da 10μA a matsakaicin ƙarfin wutar baya na 5V. An ƙayyade jurewa kamar ±11% don ƙarfin haske, ±1nm don tsawon zangon haske, da ±0.1V don ƙarfin wutar gaba.

3. Bayanin Tsarin Rarrabawa (Binning) Don tabbatar da daidaito a cikin haske da launi a aikace-aikacen samarwa, ana rarraba LED ɗin zuwa kwandon shara bisa mahimman ma'auni. Wannan yana ba masu ƙira damar zaɓar madaidaicin matakin don bukatun aikace-aikacen su.

3.1 Rarrabawar Ƙarfin Hasken (Luminous Intensity) Ana rarraba fitar da haske zuwa kwandon shara huɗu: R2 (140-180 mcd), S1 (180-225 mcd), S2 (225-285 mcd), da T1 (285-360 mcd). Duk ma'aunai ana ɗaukar su a I_F=20mA. Zaɓin babban kwandon shara (misali, T1) yana ba da garantin LED mai haske, wanda zai iya zama dole don aikace-aikacen da ke buƙatar ganuwa mai girma ko lokacin amfani da shi a bayan bututun haske tare da raguwa mai yawa.

3.2 Rarrabawar Tsawon Zangon Haske (Dominant Wavelength) Ana sarrafa launi (hue) ta hanyar rarraba tsawon zangon haske. Don wannan jerin ja mai haske, an haɗa kwandon shara a ƙarƙashin lambar 'F', tare da ƙananan kwandon shara FF1 (621-626 nm) da FF2 (626-631 nm). Matsakaicin rarraba tsawon zango a cikin aikace-aikace yana tabbatar da kamannin launi iri ɗaya a cikin alamomi da yawa.R3.3 Rarrabawar Ƙarfin Wutar Gaba (Forward Voltage) Ana rarraba ƙarfin wutar gaba zuwa ƙungiyoyi uku a ƙarƙashin lambar 'B': B0 (1.75-1.95V), B1 (1.95-2.15V), da B2 (2.15-2.35V). Sanin kwandon shara na V_F yana da mahimmanci don ƙirar da'irar iyakancewa na yanzu, musamman lokacin tuƙi LED da yawa a jere, don tabbatar da rarraba yanzu daidai da haske.F4. Binciken Lanƙwan Ayyuka Lanƙwan halaye da aka bayar suna ba da haske mai mahimmanci game da halayen LED a ƙarƙashin yanayin da ba daidai ba.FP4.1 Matsakaicin Hasken Dangane da Yanayin Zafi Lanƙwan yana nuna cewa ƙarfin haske yana da alaƙa da juzu'in zafin jiki. Yayin da yanayin zafi ya tashi daga -40°C zuwa +110°C, fitarwa na dangi yana raguwa. A matsakaicin zafin aiki na +85°C, fitarwa ya fi ƙasa sosai fiye da a 25°C. Dole ne a yi la'akari da wannan raguwar zafin jiki a cikin ƙira inda ake tsammanin yanayin zafi mai girma, mai yuwuwa yana buƙatar zaɓin kwandon shara mai ƙarfi ko sanyaya mai aiki.d4.2 Ƙarfin Wutar Gaba Dangane da ƙarfin Wuta (Lanƙwan I-V) Lanƙwan I-V ba shi da layi, na yau da kullun na diode. A wurin aiki na shawarar 20mA, ƙarfin wutar lantarki ya faɗi cikin kewayon kwandon shara. Lanƙwan yana ba masu ƙira damar kimanta raguwar wutar lantarki a ƙarfin tuƙi daban-daban, wanda ke da mahimmanci don ƙirar samar da wutar lantarki.

4.3 Matsakaicin Hasken Dangane da ƙarfin Wutar Gaba Wannan lanƙwan yana nuna cewa fitar da haske yana daidai da kusan ƙarfin wutar gaba a cikin kewayon aiki na yau da kullun. Duk da haka, an haramta tuƙi LED sama da iyakar cikakke na 25mA, saboda zai rage rayuwa da aminci saboda samar da zafi mai yawa.

4.4 Tsarin Watsa Hasken da Rarraba Bakan Haske Zanen watsa haske yana tabbatar da faɗin kallon digiri 120, yana nuna tsarin watsa haske mai kama da Lambertian. Taswirar rarraba bakan haske tana nuna kololuwa guda ɗaya a tsakiya kusan 632nm, wanda ke da halayen LED ja na AlGaInP, tare da ƙayyadaddun faɗin bakan da ke tabbatar da tsaftar launi.v5. Bayanan Injiniya da Kunshi Kunshin P-LCC-2 yana da girma kusan 3.2mm a tsayi, 2.8mm a faɗi, da 1.9mm a tsayi (jurewa ±0.1mm sai dai idan an faɗi). Zanen fasaha yana ba da cikakkun ma'auni don jikin LED, ruwan tabarau, da mahimman ƙafar ƙafar solder. Ƙirar ƙafar daidai tana da mahimmanci don solder mai aminci da daidaitawar daidai yayin sake kunnawa. Ana nuna polarity ta alamar cathode akan kunshin. Tsarin ƙasa na PCB da aka ba da shawarar yana tabbatar da isasshen samuwar fillet na solder da kwanciyar hankali na injiniya.d6. Jagororin Solder da Haɗawa Na'urar tana cikakkiyar dacewa da daidaitattun hanyoyin haɗawa na SMT. Don sake kunnawa solder, ana buƙatar bayanin martaba tare da matsakaicin zafin jiki bai wuce 260°C ba na dakika 10 don hana lalata kunshin filastik da haɗin guntu na ciki. Ya kamata a bi matsakaicin haɓakawa da ƙimar sanyaya. Don solder da hannu, dole ne a yi taka tsantsan: yi amfani da ƙarfe mai ƙasa tare da zafin ƙarshen ƙasa da 350°C, kuma a iyakance lokacin tuntuɓar kowane ƙafar zuwa dakika 3. Guji damuwa na injiniya akan ruwan tabarau yayin haɗawa da bayansa. Ana magance hankalin danshi ta hanyar jigilar abubuwan a cikin jakunkunan kariya na aluminum masu rufi tare da busasshiyar abu.p7. Bayanan Kunshi da Oda Ana ba da LED ɗin akan kaset ɗin ɗaukar kaya na 8mm, tare da daidaitaccen adadin da aka ɗora na guda 2000 a kowace reel. An ƙayyade girman reel don dacewa da masu ciyar da atomatik. Alamar da ke kan reel ta haɗa da mahimman bayanai: Lambar Sashe (PN), Lambar Sashe na Abokin Ciniki (CPN), adadi (QTY), lambar kuri'a (LOT NO), da takamaiman lambobin kwandon shara don ƙarfin haske (CAT), tsawon zangon haske (HUE), da ƙarfin wutar gaba (REF). Wannan bin diddigin yana da mahimmanci don sarrafa inganci da daidaitaccen masana'anta.F8. Shawarwarin Aikace-aikace 8.1 Yanayin Aikace-aikace na Yau da Kullun Wannan LED ta dace don alamomin matsayi a cikin na'urorin lantarki na mabukaci, hasken baya don maɓallan membrane da almara na panel, da hasken bututun haske a cikin allunan motoci ko allunan sarrafa masana'antu. Faɗin kallonsa yana sa ya dace don aikace-aikacen da ake buƙatar ganin alama daga kusurwoyi daban-daban.R8.2 Abubuwan Da Ake Bukatar Yi La'akari Da Su A Zance Koyaushe yi amfani da resistor mai iyakancewa na yanzu a jere tare da LED. Ƙimar resistor (R) za a iya ƙididdige ta ta amfani da R = (V_supply - V_F) / I_F. Yi amfani da matsakaicin V_F daga kwandon shara ko takardar bayanai don tabbatar da cewa yanzu bai wuce 20mA ba a ƙarƙashin yanayi mafi muni. Don daidaitaccen haske a cikin tsararrun LED da yawa, yi la'akari da amfani da direbobi na yanzu na akai ko rarraba LED don daidaitaccen V_F. Lokacin amfani da bututun haske, tabbatar da cewa kayan bututun suna da babban watsawa don hasken ja kuma ƙira mahaɗin don rage asarar gani.

9. Aminci da Tabbatar da Inganci Samfurin yana ƙarƙashin cikakken jerin gwaje-gwajen aminci tare da matakin amincewa na 90% da Kashi na Rashin Ingantaccen Kuri'a na 10% (LTPD). Fayil ɗin gwajin ya haɗa da juriya na sake kunnawa solder, zagayowar zafin jiki (-40°C zuwa +100°C), girgiza zafi, ajiyar zafi mai girma da ƙasa, rayuwar aikin DC a 20mA na sa'o'i 1000, da gwajin zafi mai girma/ɗanɗano mai girma (85°C/85% RH). Waɗannan gwaje-gwajen suna tabbatar da ƙarfin LED don yanayin mota da masana'antu masu ƙarfi, suna tabbatar da kwanciyar hankali na aiki na dogon lokaci.

10. Kwatancen Fasaha da Bambance-bambance Idan aka kwatanta da tsofaffin LED na rami, wannan kunshin SMD yana ba da tanadin sarari mai mahimmanci, mafi dacewa don samar da atomatik, da ingantaccen aminci ta hanyar kawar da solder da hannu. A cikin yanayin LED na SMD, jerin 67-21 sun bambanta kansu da takamaiman lissafin kunshin da aka inganta don haɗawar bututun haske da faɗin kallonsa na digiri 120, wanda ya fi yawancin LED na SMD na yau da kullun. Samun daidaitaccen rarrabawa don ƙarfi, launi, da ƙarfin wutar lantarki yana ba da fa'ida don aikace-aikacen da ke buƙatar daidaito mai girma.

11. Tambayoyin Da Ake Yawan Yi (FAQs) Q: Shin zan iya tuƙi wannan LED ba tare da resistor mai iyakancewa ba? A: A'a. LED na'urar ce da aka tuƙa ta yanzu. Haɗa shi kai tsaye zuwa tushen wutar lantarki zai haifar da wuce gona da iri na yanzu, wanda zai lalata shi nan take. Koyaushe yi amfani da resistor na jere ko direba na yanzu na akai. Q: Menene bambanci tsakanin tsawon zango kololuwa da tsawon zangon haske? A: Tsawon zango kololuwa (λ_P) shine tsawon zango inda rarraba ƙarfin bakan haske ya fi girma. Tsawon zangon haske (λ_D) shine tsawon zango guda ɗaya na hasken monochromatic wanda ya dace da launin da aka gane na LED. Don ƙayyadaddun launi, tsawon zangon haske ya fi dacewa. Q: Ta yaya zan fassara lambobin kwandon shara akan lakabin? A: Lambar CAT ta dace da kwandon shara na ƙarfin haske (misali, S1), lambar HUE zuwa kwandon shara na tsawon zangon haske (misali, FF1), da lambar REF zuwa kwandon shara na ƙarfin wutar gaba (misali, B1). Waɗannan suna tabbatar da cewa kuna karɓar LED tare da takamaiman halayen aiki da kuka oda. Q: Shin ana buƙatar sink na zafi? A: Don aikin al'ada a 20mA ko ƙasa, ba a yawanci buƙatar takamaiman sink na zafi don LED guda ɗaya. Duk da haka, sarrafa zafi ta hanyar daidaitaccen shimfidar PCB (ƙafafin taimakon zafi, zubar da tagulla) kyakkyawan aiki ne, musamman don tsararrun yawa ko aikace-aikacen yanayin zafi mai girma.

12. Misalan Zance da Amfani na Aiki Misali 1: Gungun Nuna Alama na Allon Nuni: A cikin allon mota, ana iya ɗora LED 67-21 da yawa (a cikin ja da sauran launuka daga jerin) akan PCB guda ɗaya. Kowane LED yana haɗe da takamaiman bututun haske don jagorantar haskensa zuwa takamaiman alama (misali, duba injin, matsa lamba na mai). Faɗin kallon yana tabbatar da cewa an haskaka alama daidai ga direba da fasinja. Ana tuƙi LED ta hanyar tsarin 12V na abin hawa ta amfani da madaidaicin resistors na jere, waɗanda aka ƙididdige su ta amfani da matsakaicin V_F don tabbatar da daidaiton haske a cikin kewayon zafin jiki a cikin mota. Misali 2: Panel Sarrafa Masana'antu: Panel ma'aikacin inji yana amfani da waɗannan LED a bayan allunan acrylic da aka zana don nuna jihohin inji (Aiki - Kore, Laifi - Ja, Jiran Aiki - Yellow). Farin kunshin LED yana rage gurɓataccen launi daga PCB. Mai zane yana zaɓar LED daga kwandon shara iri ɗaya na ƙarfi da ƙarfin wutar lantarki don ba da garantin daidaitaccen haske a duk alamomi. Kunshin SMD yana ba da damar ƙira panel mai lebur sosai da ƙanƙanta.F13. Ka'idar Aiki Wannan LED tana aiki bisa ka'idar electroluminescence a cikin mahaɗar p-n semiconductor. Kayan guntu shine Aluminum Gallium Indium Phosphide (AlGaInP). Lokacin da aka yi amfani da ƙarfin wutar gaba wanda ya wuce ƙofar diode, electrons daga yankin n da ramuka daga yankin p ana shigar da su cikin yankin aiki inda suke sake haɗuwa. A cikin AlGaInP, wannan sake haɗuwa yana sakin makamashi a cikin nau'in photons (haske) a cikin ɓangaren ja na bakan gani (kusan 630nm). Takamaiman abun da ke cikin AlGaInP yana ƙayyade daidai tsawon zangon hasken da aka fitar. Ruwan tabarau na epoxy mara launi yana ɗauke da guntu, yana kare shi daga muhalli, kuma yana siffanta hasken da aka fitar zuwa tsarin watsa haske da ake so.

14. Trends na Masana'antu da Mahallin Trend a cikin LED na nuna alama yana ci gaba zuwa mafi inganci (ƙarin fitar da haske a kowace raka'a na shigar da lantarki), ƙananan girman kunshi, da ingantaccen aminci. Hakanan akwai ƙara buƙatar ƙaramin daidaito na launi da haske (rarrabawa) saboda dalilai na ado da aiki a cikin na'urorin lantarki na mabukaci da na mota. Yayin da wannan jerin 67-21 samfur ne da aka kafa sosai, sabbin fasahohin LED na iya ba da inganci mafi girma. Duk da haka, haɗin kunshin da aka tabbatar, samuwa mai yawa, takamaiman halayen gani don bututun haske, da cikakkun bayanan aminci suna tabbatar da ci gaba da dacewarsa a yawancin aikace-aikacen ƙira inda ake buƙatar daidaita aiki, farashi, da ingantaccen aminci. Tuƙi don ƙananan ƙira da haɗakarwa mafi girma a cikin na'urorin lantarki kuma yana goyan bayan amfani da irin waɗannan daidaitattun abubuwan SMD masu sarrafa kansa.

The color (hue) is controlled by binning the dominant wavelength. For this brilliant red series, the bins are grouped under code 'F', with sub-bins FF1 (621-626 nm) and FF2 (626-631 nm). A tighter wavelength distribution within an application ensures a uniform color appearance across multiple indicators.

.3 Forward Voltage Binning

The forward voltage is binned into three groups under code 'B': B0 (1.75-1.95V), B1 (1.95-2.15V), and B2 (2.15-2.35V). Knowledge of the VFbin is crucial for designing current-limiting circuitry, especially when driving multiple LEDs in series, to ensure uniform current distribution and brightness.

. Performance Curve Analysis

The provided characteristic curves offer valuable insights into the LED's behavior under non-standard conditions.

.1 Relative Luminous Intensity vs. Ambient Temperature

The curve shows that luminous intensity is inversely related to junction temperature. As the ambient temperature rises from -40°C to +110°C, the relative output decreases. At the maximum operating temperature of +85°C, the output is significantly lower than at 25°C. This thermal derating must be accounted for in designs where high ambient temperatures are expected, potentially requiring the selection of a higher intensity bin or active cooling.

.2 Forward Current vs. Forward Voltage (I-V Curve)

The I-V curve is non-linear, typical of a diode. At the recommended 20mA operating point, the voltage falls within the binned range. The curve allows designers to estimate the voltage drop at different drive currents, which is essential for power supply design.

.3 Relative Luminous Intensity vs. Forward Current

This curve demonstrates that light output is approximately proportional to forward current in the typical operating range. However, driving the LED above the absolute maximum rating of 25mA is prohibited, as it will reduce lifetime and reliability due to excessive heat generation.

.4 Radiation Pattern and Spectrum Distribution

The radiation diagram confirms the wide 120-degree viewing angle, showing a Lambertian-like emission pattern. The spectral distribution plot shows a single peak centered around 632nm, which is characteristic of AlGaInP red LEDs, with a defined bandwidth ensuring color purity.

. Mechanical and Package Information

The P-LCC-2 package has dimensions of approximately 3.2mm in length, 2.8mm in width, and 1.9mm in height (tolerance ±0.1mm unless otherwise noted). The technical drawing provides detailed measurements for the LED body, lens, and the critical solder pad footprint. Correct pad design is essential for reliable soldering and proper alignment during reflow. The polarity is indicated by the cathode mark on the package. The recommended PCB land pattern ensures sufficient solder fillet formation and mechanical stability.

. Soldering and Assembly Guidelines

The device is fully compatible with standard SMT assembly processes. For reflow soldering, a profile with a peak temperature not exceeding 260°C for 10 seconds is mandatory to prevent damage to the plastic package and the internal die bond. A standard ramp-up and cooling rate should be followed. For hand soldering, extreme care must be taken: use a grounded iron with a tip temperature below 350°C, and limit the contact time to 3 seconds per pad. Avoid mechanical stress on the lens during and after assembly. Moisture sensitivity is addressed by shipping the components in sealed aluminum moisture-proof bags with desiccant.

. Packaging and Ordering Information

The LEDs are supplied on 8mm carrier tape, with a standard loaded quantity of 2000 pieces per reel. The reel dimensions are specified for compatibility with automated feeders. The labeling on the reel includes critical information: Part Number (PN), Customer Part Number (CPN), quantity (QTY), lot number (LOT NO), and the specific bin codes for luminous intensity (CAT), dominant wavelength (HUE), and forward voltage (REF). This traceability is vital for quality control and consistent manufacturing.

. Application Recommendations

.1 Typical Application Scenarios

This LED is ideal for status indicators in consumer electronics, backlighting for membrane switches and panel legends, and illumination for light pipes in automotive dashboards or industrial control panels. Its wide viewing angle makes it suitable for applications where the indicator needs to be visible from various angles.

.2 Design Considerations

Always use a current-limiting resistor in series with the LED. The resistor value (R) can be calculated using R = (Vsupply- VF) / IF. Use the maximum VFfrom the bin or datasheet to ensure the current does not exceed 20mA under worst-case conditions. For uniform brightness in multi-LED arrays, consider using constant current drivers or binning LEDs for consistent VF. When using with light pipes, ensure the pipe material has high transmittance for red light and design the interface to minimize optical losses.

. Reliability and Quality Assurance

The product undergoes a comprehensive suite of reliability tests with a 90% confidence level and 10% Lot Tolerance Percent Defective (LTPD). The test portfolio includes reflow soldering resistance, temperature cycling (-40°C to +100°C), thermal shock, high and low temperature storage, DC operating life at 20mA for 1000 hours, and high temperature/high humidity (85°C/85% RH) testing. These tests validate the LED's robustness for demanding automotive and industrial environments, ensuring long-term performance stability.

. Technical Comparison and Differentiation

Compared to older through-hole LEDs, this SMD package offers significant space savings, better suitability for automated production, and improved reliability by eliminating manual soldering. Within the SMD LED landscape, the 67-21 series differentiates itself with its specific package geometry optimized for light pipe coupling and its wide 120-degree viewing angle, which is broader than many standard SMD LEDs. The availability of precise binning for intensity, color, and voltage provides an advantage for applications requiring high consistency.

. Frequently Asked Questions (FAQs)

Q: Can I drive this LED without a current-limiting resistor?

A: No. An LED is a current-driven device. Connecting it directly to a voltage source will cause excessive current to flow, instantly destroying it. Always use a series resistor or a constant-current driver.

Q: What is the difference between peak wavelength and dominant wavelength?

A: Peak wavelength (λp) is the wavelength at which the spectral power distribution is maximum. Dominant wavelength (λd) is the single wavelength of monochromatic light that matches the perceived color of the LED. For color specification, dominant wavelength is more relevant.

Q: How do I interpret the bin codes on the label?

A: The CAT code corresponds to the luminous intensity bin (e.g., S1), the HUE code to the dominant wavelength bin (e.g., FF1), and the REF code to the forward voltage bin (e.g., B1). These ensure you receive LEDs with the specific performance characteristics you ordered.

Q: Is a heat sink required?

A: For normal operation at 20mA or below, a dedicated heat sink is not typically required for a single LED. However, thermal management through proper PCB layout (thermal relief pads, copper pours) is good practice, especially for high-density arrays or high ambient temperature applications.

. Practical Design and Usage Examples

Example 1: Dashboard Indicator Cluster:In an automotive dashboard, multiple 67-21 LEDs (in red and other colors from the series) can be mounted on a single PCB. Each LED is paired with a dedicated light pipe to guide its light to a specific icon (e.g., check engine, oil pressure). The wide viewing angle ensures the icon is illuminated evenly for both the driver and passenger. The LEDs are driven via the vehicle's 12V system using appropriate series resistors, calculated using the maximum VFto ensure brightness consistency across the temperature range inside the car.

Example 2: Industrial Control Panel:A machine operator panel uses these LEDs behind engraved acrylic panels to indicate machine states (Running - Green, Fault - Red, Standby - Yellow). The white package of the LED minimizes color contamination from the PCB. The designer selects LEDs from the same intensity and voltage bin to guarantee uniform brightness across all indicators. The SMD package allows for a very flat and compact panel design.

. Operational Principle

This LED operates on the principle of electroluminescence in a semiconductor p-n junction. The chip material is Aluminum Gallium Indium Phosphide (AlGaInP). When a forward voltage exceeding the diode's threshold is applied, electrons from the n-region and holes from the p-region are injected into the active region where they recombine. In AlGaInP, this recombination releases energy in the form of photons (light) in the red portion of the visible spectrum (approximately 630nm). The specific composition of the AlGaInP layers determines the precise wavelength of the emitted light. The colorless clear epoxy lens encapsulates the chip, protects it from the environment, and shapes the emitted light into the desired radiation pattern.

. Industry Trends and Context

The trend in indicator LEDs continues towards higher efficiency (more light output per unit of electrical input), smaller package sizes, and improved reliability. There is also a growing demand for tighter color and brightness consistency (binning) for aesthetic and functional reasons in consumer and automotive electronics. While this 67-21 series is a well-established product, newer LED technologies may offer higher efficacy. However, its combination of a proven package, wide availability, specific optical characteristics for light piping, and comprehensive reliability data ensures its continued relevance in many design applications where a balance of performance, cost, and proven reliability is required. The drive for miniaturization and higher integration in electronics also supports the use of such standardized, automatable SMD components.

Kalmomin Ƙayyadaddun LED

Cikakken bayanin kalmomin fasaha na LED

Aikin Hasken Wutar Lantarki

| Kalma | Naúrar/Wakilci | Bayanin Sauri | Me yasa yake da muhimmanci |

|---|---|---|---|

| Ingancin Hasken Wuta | lm/W (lumen kowace watt) | Fitowar haske kowace watt na wutar lantarki, mafi girma yana nufin mafi ingancin kuzari. | Kai tsaye yana ƙayyade matakin ingancin kuzari da farashin wutar lantarki. |

| Gudun Hasken Wuta | lm (lumen) | Jimillar hasken da tushe ke fitarwa, ana kiransa "haske". | Yana ƙayyade ko hasken yana da haske sosai. |

| Kusurwar Dubawa | ° (digiri), misali 120° | Kusurwar da ƙarfin haske ya ragu zuwa rabi, yana ƙayyade faɗin haske. | Yana shafar kewar haskakawa da daidaito. |

| Zafin Launi (CCT) | K (Kelvin), misali 2700K/6500K | Zafi/sanyin haske, ƙananan ƙimomi rawaya/zafi, mafi girma fari/sanyi. | Yana ƙayyade yanayin haskakawa da yanayin da suka dace. |

| CI / Ra | Ba naúrar, 0–100 | Ikon ba da launukan abubuwa daidai, Ra≥80 yana da kyau. | Yana shafar sahihancin launi, ana amfani dashi a wurare masu buƙatu kamar shaguna, gidajen tarihi. |

| SDCM | Matakan ellipse MacAdam, misali "5-mataki" | Ma'aunin daidaiton launi, ƙananan matakai suna nufin mafi daidaiton launi. | Yana tabbatar da daidaiton launi a cikin rukunin LED iri ɗaya. |

| Matsakaicin Tsawon Raɗaɗin Hasken | nm (nanomita), misali 620nm (ja) | Tsawon raɗaɗin haske daidai da launin LED masu launi. | Yana ƙayyade launin ja, rawaya, kore LED masu launi ɗaya. |

| Rarraba Bakan Hasken | Layin tsawon raɗaɗi da ƙarfi | Yana nuna rarraba ƙarfi a cikin tsawon raɗaɗin haske. | Yana shafar ba da launi da ingancin launi. |

Ma'auni na Lantarki

| Kalma | Alamar | Bayanin Sauri | Abubuwan ƙira |

|---|---|---|---|

| Ƙarfin lantarki na gaba | Vf | Mafi ƙarancin ƙarfin lantarki don kunna LED, kamar "maƙallan farawa". | Ƙarfin lantarki na injin dole ya zama ≥Vf, ƙarfin lantarki yana ƙara don LED a jere. |

| Ƙarfin lantarki na gaba | If | Ƙimar ƙarfin lantarki don aikin LED na yau da kullun. | Yawanci tuƙi mai ƙarfi akai-akai, ƙarfin lantarki yana ƙayyade haske da tsawon rai. |

| Matsakaicin Ƙarfin lantarki na bugun jini | Ifp | Matsakaicin ƙarfin lantarki mai jurewa na ɗan lokaci, ana amfani dashi don duhu ko walƙiya. | Fadin bugun jini da sake zagayowar aiki dole ne a sarrafa su sosai don guje wa lalacewa. |

| Ƙarfin lantarki na baya | Vr | Matsakaicin ƙarfin lantarki na baya da LED zai iya jurewa, wanda ya wuce zai iya haifar da rushewa. | Dangane dole ne ya hana haɗin baya ko ƙarfin lantarki. |

| Juriya na zafi | Rth (°C/W) | Juriya ga canja wurin zafi daga guntu zuwa solder, ƙasa yana da kyau. | Babban juriya na zafi yana buƙatar zubar da zafi mai ƙarfi. |

| Rigakafin ESD | V (HBM), misali 1000V | Ikon jurewa zubar da wutar lantarki, mafi girma yana nufin ƙasa mai rauni. | Ana buƙatar matakan hana wutar lantarki a cikin samarwa, musamman ga LED masu hankali. |

Gudanar da Zafi & Amincewa

| Kalma | Ma'aunin maɓalli | Bayanin Sauri | Tasiri |

|---|---|---|---|

| Zazzabin Haɗin gwiwa | Tj (°C) | Ainihin yanayin aiki a cikin guntun LED. | Kowane raguwa 10°C na iya ninka tsawon rai; yayi yawa yana haifar da lalacewar haske, canjin launi. |

| Ragewar Lumen | L70 / L80 (sa'o'i) | Lokacin da haske ya ragu zuwa 70% ko 80% na farko. | Kai tsaye yana ayyana "tsawon sabis" na LED. |

| Kula da Lumen | % (misali 70%) | Kashi na hasken da aka riƙe bayan lokaci. | Yana nuna riƙon haske akan amfani na dogon lokaci. |

| Canjin Launi | Δu′v′ ko ellipse MacAdam | Matsakaicin canjin launi yayin amfani. | Yana shafar daidaiton launi a cikin yanayin haskakawa. |

| Tsufa na Zafi | Lalacewar kayan aiki | Lalacewa saboda yanayin zafi na dogon lokaci. | Zai iya haifar da raguwar haske, canjin launi, ko gazawar buɗe kewaye. |

Tufafi & Kayan Aiki

| Kalma | Nau'ikan gama gari | Bayanin Sauri | Siffofi & Aikace-aikace |

|---|---|---|---|

| Nau'in Kunshin | EMC, PPA, Yumbu | Kayan gida masu kare guntu, samar da hanyar sadarwa ta gani/zafi. | EMC: juriya mai kyau na zafi, farashi mai rahusa; Yumbu: mafi kyawun zubar da zafi, tsawon rai. |

| Tsarin Guntu | Gaba, Guntu Juyawa | Tsarin na'urorin lantarki na guntu. | Juyawar guntu: mafi kyawun zubar da zafi, inganci mafi girma, don ƙarfi mai ƙarfi. |

| Rufin Phosphor | YAG, Silicate, Nitride | Yana rufe guntu shuɗi, yana canza wasu zuwa rawaya/ja, yana haɗa su zuwa fari. | Phosphor daban-daban suna shafar inganci, CCT, da CRI. |

| Ruwan tabarau/Optics | Lefi, Microlens, TIR | Tsarin gani a saman yana sarrafa rarraba haske. | Yana ƙayyade kusurwar dubawa da layin rarraba haske. |

Kula da Inganci & Rarraba

| Kalma | Abun rarraba | Bayanin Sauri | Manufa |

|---|---|---|---|

| Kwalin Gudun Hasken | Lambar misali 2G, 2H | An tattara su ta hanyar haske, kowace ƙungiya tana da ƙananan/matsakaicin ƙimar lumen. | Yana tabbatar da daidaiton haske a cikin jeri ɗaya. |

| Kwalin Ƙarfin lantarki | Lambar misali 6W, 6X | An tattara su ta hanyar kewayon ƙarfin lantarki na gaba. | Yana sauƙaƙe daidaitawar tuƙi, yana inganta ingancin tsarin. |

| Kwalin Launi | Ellipse MacAdam 5-mataki | An tattara su ta hanyar daidaitattun launi, yana tabbatar da ƙuntataccen kewayon. | Yana ba da garantin daidaiton launi, yana guje wa launi mara daidaituwa a cikin kayan aikin. |

| Kwalin CCT | 2700K, 3000K da sauransu | An tattara su ta hanyar CCT, kowanne yana da madaidaicin kewayon daidaitawa. | Yana cika buƙatun CCT na yanayi daban-daban. |

Gwaji & Takaddun Shaida

| Kalma | Matsakaicin/Gwaji | Bayanin Sauri | Muhimmanci |

|---|---|---|---|

| LM-80 | Gwajin kula da lumen | Haskakawa na dogon lokaci a yanayin zafi akai-akai, yana rikodin lalacewar haske. | Ana amfani dashi don kimanta rayuwar LED (tare da TM-21). |

| TM-21 | Matsakaicin kimanta rayuwa | Yana kimanta rayuwa a ƙarƙashin yanayi na ainihi bisa bayanan LM-80. | Yana ba da hasashen kimiyya na rayuwa. |

| IESNA | Ƙungiyar Injiniyoyin Haskakawa | Yana rufe hanyoyin gwajin gani, lantarki, zafi. | Tushen gwaji da masana'antu suka amince. |

| RoHS / REACH | Tabbatarwar muhalli | Yana tabbatar da babu abubuwa masu cutarwa (darma, mercury). | Bukatar shiga kasuwa a duniya. |

| ENERGY STAR / DLC | Tabbatarwar ingancin kuzari | Tabbatarwar ingancin kuzari da aiki don samfuran haskakawa. | Ana amfani dashi a cikin sayayyan gwamnati, shirye-shiryen tallafi, yana haɓaka gasa. |