Table of Contents

- 1. Product Overview

- 2. Technical Parameters Deep Objective Interpretation

- 2.1 Absolute Maximum Ratings

- 2.2 Electrical and Transfer Characteristics

- 3. Switching Characteristics

- 4. Mechanical and Package Information

- 4.1 Pin Configuration

- 5. Application Suggestions

- 5.1 Typical Application Scenarios

- 5.2 Design Considerations

- 6. Technical Comparison and Selection Guide

- 7. Frequently Asked Questions (Based on Technical Parameters)

- 8. Principle Introduction

- 9. Packaging and Ordering Information

1. Product Overview

The 6N135, 6N136, EL4502, and EL4503 are a family of high-speed transistor output photocouplers (optoisolators) designed for applications requiring fast digital signal isolation. Each device integrates an infrared light-emitting diode (LED) optically coupled to a high-speed photodetector transistor. The core advantage of this series lies in its dedicated pinout, which separates the photodiode bias and the output transistor's collector. This architectural choice significantly reduces the base-collector capacitance of the input transistor, enabling switching speeds up to 1 Megabit per second (1Mbit/s), which is orders of magnitude faster than conventional phototransistor-based couplers.

The devices are offered in a standard 8-pin Dual In-line Package (DIP) and are available with options for wide lead spacing and surface-mount configurations. They are characterized for operation over a wide temperature range and are compliant with major international safety standards, making them suitable for industrial, telecommunications, and power electronics applications.

2. Technical Parameters Deep Objective Interpretation

2.1 Absolute Maximum Ratings

The Absolute Maximum Ratings define the stress limits beyond which permanent damage to the device may occur. Operating the device continuously at or near these limits is not recommended. Key ratings include:

- Input Forward Current (IF): 25 mA continuous. The peak forward current (IFP) is rated at 50 mA for pulses with a 50% duty cycle and 1ms pulse width.

- Reverse Voltage (VR): 5 V maximum across the input LED.

- Output Voltage (VO): Range from -0.5 V to +20 V at the output pin.

- Supply Voltage (VCC): Range from -0.5 V to +30 V for the output side power supply.

- Isolation Voltage (VISO): 5000 Vrms for 1 minute. This is a critical safety parameter, tested by shorting the input-side pins (1-4) together and the output-side pins (5-8) together.

- Operating Temperature (TOPR): -55°C to +100°C. This wide range ensures reliable performance in harsh environments.

- Total Power Dissipation (PTOT): 200 mW, combining input and output power limits.

2.2 Electrical and Transfer Characteristics

These parameters are guaranteed over the operating temperature range of 0°C to 70°C unless otherwise noted. They define the device's performance under normal operating conditions.

- Forward Voltage (VF): Typically 1.45V at IF = 16 mA. This is important for designing the input-side current limiting circuit.

- Current Transfer Ratio (CTR): This is the ratio of the output transistor's collector current to the input LED's forward current, expressed as a percentage. The 6N135 has a minimum CTR of 7% (typ. scenario), while the 6N136, EL4502, and EL4503 have a minimum of 19%. This parameter directly affects the required drive current for a given output current.

- Logic Low Output Voltage (VOL): The voltage at the output pin when the device is in the "ON" state. For the 6N135, it is guaranteed to be below 0.4V (max) at IF=16mA and IO=1.1mA. For the 6N136/EL450x, it's below 0.4V at IO=3mA. Low VOL is crucial for clean logic-low signals.

- Supply Currents (ICCL, ICCH): ICCL is the current drawn from VCC when the output is low (LED on), typically 140 µA. ICCH is the current when the output is high (LED off), typically 0.01 µA, indicating very low power consumption in the idle state.

3. Switching Characteristics

These parameters quantify the device's speed, which is its primary differentiator. Tests are performed at IF=16mA and VCC=5V.

- Propagation Delay (tPHL, tPLH): This is the time delay between the input signal edge and the corresponding output response.

- 6N135: tPHL (to Low) is typically 0.35 µs (max 2.0 µs); tPLH (to High) is typically 0.5 µs (max 2.0 µs) with RL=4.1kΩ.

- 6N136/EL450x: tPHL is typically 0.35 µs (max 1.0 µs); tPLH is typically 0.3 µs (max 1.0 µs) with RL=1.9kΩ.

- Common Mode Transient Immunity (CMH, CML): This measures the device's ability to reject fast voltage transients (noise) that appear equally on both the input and output sides of the isolation barrier. It is specified in Volts per microsecond (V/µs).

- 6N135/6N136/EL4502: Minimum 1000 V/µs for both high and low states.

- EL4503: Significantly higher, with a typical value of 20,000 V/µs and a minimum of 15,000 V/µs, making it ideal for very noisy environments like motor drives.

4. Mechanical and Package Information

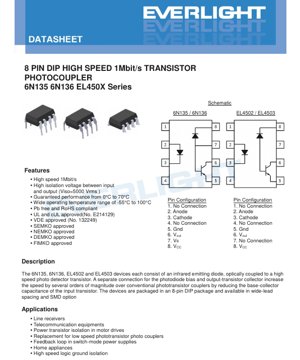

4.1 Pin Configuration

The devices use an 8-pin DIP package. The pinout differs slightly between the 6N135/6N136 and the EL4502/EL4503, primarily in the function of pin 7.

For 6N135 / 6N136:

- No Connection (NC)

- Anode (Input LED Anode)

- Cathode (Input LED Cathode)

- No Connection (NC)

- Ground (Output side ground, GND)

- Output Voltage (VOUT)

- Bias Voltage (VB) - This pin provides a separate connection to bias the internal photodiode, which is key to achieving high speed.

- Supply Voltage (VCC)

For EL4502 / EL4503:

- No Connection (NC)

- Anode (Input LED Anode)

- Cathode (Input LED Cathode)

- No Connection (NC)

- Ground (Output side ground, GND)

- Output Voltage (VOUT)

- No Connection (NC) - Note: Pin 7 is not connected in these variants.

- Supply Voltage (VCC)

5. Application Suggestions

5.1 Typical Application Scenarios

- Line Receivers & Telecommunications Equipment: Isolating digital data lines (e.g., RS-232, RS-485) to prevent ground loops and protect sensitive circuitry from surges.

- Power Transistor Isolation in Motor Drives & Switch-Mode Power Supplies (SMPS): Providing gate drive signals to high-side power MOSFETs/IGBTs while maintaining galvanic isolation. The high common-mode transient immunity (especially of the EL4503) is critical here.

- High-Speed Logic Ground Isolation: Breaking ground loops between digital subsystems operating at different potentials, preventing noise coupling.

- Replacement for Low-Speed Phototransistor Couplers: Upgrading existing designs for higher data rates without major circuit changes.

- Home Appliances & Industrial Controls: Isolating user interface microcontrollers from power stages.

5.2 Design Considerations

- Input Current Limiting: An external resistor must be used in series with the input LED to limit the forward current (IF) to the desired value, typically around 16 mA for optimal speed and CTR. The resistor value is calculated as (Supply Voltage - VF) / IF.

- Output Pull-Up Resistor: A pull-up resistor (RL) is required between VOUT (pin 6) and VCC (pin 8). Its value affects both switching speed and output current capability. The datasheet specifies test conditions with RL=4.1kΩ for 6N135 and 1.9kΩ for 6N136/EL450x. Lower values increase speed but also increase power dissipation.

- Bypass Capacitors: Place a 0.1 µF ceramic capacitor close to the VCC and GND pins on the output side to decouple high-frequency noise.

- Layout for High CMR: To maintain high common-mode rejection, minimize parasitic capacitance between the input and output sides of the circuit board layout. Keep traces on either side of the isolation barrier well separated.

6. Technical Comparison and Selection Guide

The primary differences within this series are in the Current Transfer Ratio (CTR) and the Common Mode Rejection (CMR).

- 6N135 vs. 6N136/EL4502: The 6N135 has a lower minimum CTR (7% vs. 19%). This means it may require a slightly higher input current to achieve the same output current swing. The 6N136/EL4502 offers better margin.

- EL4503 vs. Others: The EL4503 stands out with its exceptionally high common-mode transient immunity (15,000 V/µs min). This makes it the preferred choice for applications with extremely high electrical noise, such as in variable frequency drives (VFDs) or industrial motor controllers, where fast voltage spikes (dV/dt) are common.

- Selection Summary:

- For general-purpose high-speed isolation with good CTR: Choose 6N136 or EL4502.

- If cost is a major factor and lower CTR is acceptable: 6N135 may suffice.

- For the most demanding, high-noise power electronics environments: The EL4503 is specifically designed for this role.

7. Frequently Asked Questions (Based on Technical Parameters)

Q: What is the main advantage of this photocoupler over a standard 4N35?

A: Speed. The dedicated bias pin (VB on 6N135/136) architecture reduces internal capacitance, enabling operation at 1Mbit/s, whereas a standard phototransistor coupler like the 4N35 is typically limited to below 100 kbit/s.

Q: Can I use a single 5V supply for both the input and output sides?

A: Electrically, yes, but this defeats the purpose of isolation. For true isolation, the input side (LED) and output side (detector, VCC, GND) must be powered from separate, non-connected power supplies or from an isolated DC-DC converter.

Q: Why are there two different recommended pull-up resistor values (4.1kΩ vs. 1.9kΩ)?

A: The different CTR specifications of the devices lead to different optimal operating points. The 6N135, with lower CTR, uses a higher pull-up resistor to limit the output current for a given output low voltage specification, while still achieving the target speed. The 6N136/EL450x, with higher CTR, can use a lower resistor value, which can further improve switching speed.

Q: What does "Pb free and RoHS compliant" mean for my assembly process?

A: It means the device is manufactured without lead (Pb) and complies with the Restriction of Hazardous Substances directive. This allows it to be used in products sold in regions with these environmental regulations. The soldering temperature rating (260°C for 10 seconds) is specified for lead-free solder processes.

8. Principle Introduction

A transistor output photocoupler operates on the principle of optical isolation. An electrical current applied to the input side causes an infrared Light Emitting Diode (LED) to emit light. This light travels across a small gap within the package and strikes the base region of a phototransistor on the output side. The incoming photons generate electron-hole pairs in the base, effectively acting as a base current. This "optical base current" turns the transistor on, allowing a much larger collector current to flow from VCC to the output pin, pulled low through the transistor. When the input current is zero, the LED is off, no light hits the transistor, and it remains in the off state, allowing the output pin to be pulled high by the external resistor. The key to high speed in this series is the separate connection for the internal photodiode that feeds the transistor's base, which minimizes the Miller capacitance that normally slows down phototransistors.

9. Packaging and Ordering Information

The devices follow a specific part numbering scheme: 6N13XY(Z)-V or EL450XY(Z)-V.

- X: Part number identifier (5 or 6 for 6N series; 2 or 3 for EL450 series).

- Y: Lead form option.

- None: Standard DIP-8 (0.3" row spacing), packed in tubes of 45 units.

- M: Wide lead bend (0.4" spacing), packed in tubes of 45 units.

- S: Surface mount lead form.

- Z: Tape and reel option (e.g., TA). Used with 'S' option for SMD parts, typically 1000 units per reel.

- V: Optional suffix indicating VDE approval is included.

LED Specification Terminology

Complete explanation of LED technical terms

Photoelectric Performance

| Term | Unit/Representation | Simple Explanation | Why Important |

|---|---|---|---|

| Luminous Efficacy | lm/W (lumens per watt) | Light output per watt of electricity, higher means more energy efficient. | Directly determines energy efficiency grade and electricity cost. |

| Luminous Flux | lm (lumens) | Total light emitted by source, commonly called "brightness". | Determines if the light is bright enough. |

| Viewing Angle | ° (degrees), e.g., 120° | Angle where light intensity drops to half, determines beam width. | Affects illumination range and uniformity. |

| CCT (Color Temperature) | K (Kelvin), e.g., 2700K/6500K | Warmth/coolness of light, lower values yellowish/warm, higher whitish/cool. | Determines lighting atmosphere and suitable scenarios. |

| CRI / Ra | Unitless, 0–100 | Ability to render object colors accurately, Ra≥80 is good. | Affects color authenticity, used in high-demand places like malls, museums. |

| SDCM | MacAdam ellipse steps, e.g., "5-step" | Color consistency metric, smaller steps mean more consistent color. | Ensures uniform color across same batch of LEDs. |

| Dominant Wavelength | nm (nanometers), e.g., 620nm (red) | Wavelength corresponding to color of colored LEDs. | Determines hue of red, yellow, green monochrome LEDs. |

| Spectral Distribution | Wavelength vs intensity curve | Shows intensity distribution across wavelengths. | Affects color rendering and quality. |

Electrical Parameters

| Term | Symbol | Simple Explanation | Design Considerations |

|---|---|---|---|

| Forward Voltage | Vf | Minimum voltage to turn on LED, like "starting threshold". | Driver voltage must be ≥Vf, voltages add up for series LEDs. |

| Forward Current | If | Current value for normal LED operation. | Usually constant current drive, current determines brightness & lifespan. |

| Max Pulse Current | Ifp | Peak current tolerable for short periods, used for dimming or flashing. | Pulse width & duty cycle must be strictly controlled to avoid damage. |

| Reverse Voltage | Vr | Max reverse voltage LED can withstand, beyond may cause breakdown. | Circuit must prevent reverse connection or voltage spikes. |

| Thermal Resistance | Rth (°C/W) | Resistance to heat transfer from chip to solder, lower is better. | High thermal resistance requires stronger heat dissipation. |

| ESD Immunity | V (HBM), e.g., 1000V | Ability to withstand electrostatic discharge, higher means less vulnerable. | Anti-static measures needed in production, especially for sensitive LEDs. |

Thermal Management & Reliability

| Term | Key Metric | Simple Explanation | Impact |

|---|---|---|---|

| Junction Temperature | Tj (°C) | Actual operating temperature inside LED chip. | Every 10°C reduction may double lifespan; too high causes light decay, color shift. |

| Lumen Depreciation | L70 / L80 (hours) | Time for brightness to drop to 70% or 80% of initial. | Directly defines LED "service life". |

| Lumen Maintenance | % (e.g., 70%) | Percentage of brightness retained after time. | Indicates brightness retention over long-term use. |

| Color Shift | Δu′v′ or MacAdam ellipse | Degree of color change during use. | Affects color consistency in lighting scenes. |

| Thermal Aging | Material degradation | Deterioration due to long-term high temperature. | May cause brightness drop, color change, or open-circuit failure. |

Packaging & Materials

| Term | Common Types | Simple Explanation | Features & Applications |

|---|---|---|---|

| Package Type | EMC, PPA, Ceramic | Housing material protecting chip, providing optical/thermal interface. | EMC: good heat resistance, low cost; Ceramic: better heat dissipation, longer life. |

| Chip Structure | Front, Flip Chip | Chip electrode arrangement. | Flip chip: better heat dissipation, higher efficacy, for high-power. |

| Phosphor Coating | YAG, Silicate, Nitride | Covers blue chip, converts some to yellow/red, mixes to white. | Different phosphors affect efficacy, CCT, and CRI. |

| Lens/Optics | Flat, Microlens, TIR | Optical structure on surface controlling light distribution. | Determines viewing angle and light distribution curve. |

Quality Control & Binning

| Term | Binning Content | Simple Explanation | Purpose |

|---|---|---|---|

| Luminous Flux Bin | Code e.g., 2G, 2H | Grouped by brightness, each group has min/max lumen values. | Ensures uniform brightness in same batch. |

| Voltage Bin | Code e.g., 6W, 6X | Grouped by forward voltage range. | Facilitates driver matching, improves system efficiency. |

| Color Bin | 5-step MacAdam ellipse | Grouped by color coordinates, ensuring tight range. | Guarantees color consistency, avoids uneven color within fixture. |

| CCT Bin | 2700K, 3000K etc. | Grouped by CCT, each has corresponding coordinate range. | Meets different scene CCT requirements. |

Testing & Certification

| Term | Standard/Test | Simple Explanation | Significance |

|---|---|---|---|

| LM-80 | Lumen maintenance test | Long-term lighting at constant temperature, recording brightness decay. | Used to estimate LED life (with TM-21). |

| TM-21 | Life estimation standard | Estimates life under actual conditions based on LM-80 data. | Provides scientific life prediction. |

| IESNA | Illuminating Engineering Society | Covers optical, electrical, thermal test methods. | Industry-recognized test basis. |

| RoHS / REACH | Environmental certification | Ensures no harmful substances (lead, mercury). | Market access requirement internationally. |

| ENERGY STAR / DLC | Energy efficiency certification | Energy efficiency and performance certification for lighting. | Used in government procurement, subsidy programs, enhances competitiveness. |