Table of Contents

- 1. Product Overview

- 2. In-depth Technical Parameter Analysis

- 2.1 Electrical Characteristics

- 2.2 Maximum Ratings and Thermal Characteristics

- 3. Uchambuzi wa Mviringo wa Utendaji

- 3.1 Forward Characteristics (VF-IF)

- 3.2 Reverse Characteristics (VR-IR)

- 3.3 Capacitance Characteristics (VR-Ct)

- 3.4 Surge Current Derating (IFSM – PW)

- 3.5 Transient Thermal Impedance (ZθJC)

- 4. Mechanical and Packaging Information

- 4.1 Package Outline and Dimensions

- 4.2 Pin Configuration and Polarity

- 4.3 Recommended PCB Land Pattern

- 5. Mwongozo wa Uchomaji na Usanikishaji

- 6. Mapendekezo ya Utumizi

- 6.1 Saketi ya Kawaida ya Utumizi

- 6.2 Design Considerations

- 7. Technical Comparison and Advantages

- 8. Maswali Yanayoulizwa Mara kwa Mara (FAQs)

- 9. Uchambuzi wa Kesi ya Uundaji Halisi

- 10. Kanuni ya Uendeshaji

- 11. Mwelekeo wa Teknolojia

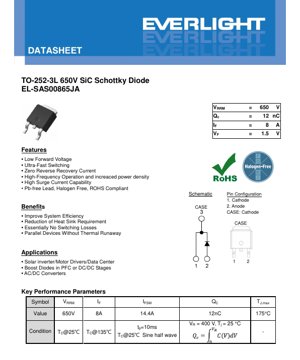

1. Product Overview

This document details the specifications of a high-performance silicon carbide Schottky barrier diode in a TO-252-3L (DPAK) surface-mount package. The device is designed for high-voltage, high-frequency power conversion applications where high efficiency, superior thermal performance, and high switching speed are critical. Its core technology leverages the superior material properties of silicon carbide, enabling operation at higher temperatures, higher voltages, and higher switching frequencies compared to traditional silicon-based diodes.

The primary role of this component is to serve as a rectifier or freewheeling diode in advanced power supply topologies. Its inherent characteristics make it an ideal choice for modern high-density power designs aimed at minimizing losses and reducing the size of passive components and heat sinks.

2. In-depth Technical Parameter Analysis

2.1 Electrical Characteristics

Electrical parameters define the operating boundaries and performance of the device under specific conditions.

- Voltage ya kilele cha nyuma inayorudiwa (VRRM):650V. Hii ndio voltage ya juu zaidi ya papo hapo ya nyuma ambayo diode inaweza kustahimili mara kwa mara. Inabainisha kiwango cha voltage cha kifaa, na ni muhimu sana kwa kuchagua diode katika mizungu kama vile urekebishaji wa sababu ya nguvu au daraja la inverter linalotolewa na voltage ya umeme ya msingi baada ya kusafishwa.

- Sasa endelevu ya mbele (IF):8A at a case temperature of 135°C. This rating indicates the current-carrying capability of the diode under continuous conduction, limited by its thermal dissipation capacity. The specification at a high case temperature highlights its robust thermal performance.

- Forward Voltage (VF):Typical value is 1.5V, maximum is 1.85V at 8A current and 25°C junction temperature. This parameter directly affects conduction loss. For SiC devices, a relatively low VF helps improve system efficiency. Please note that VF has a negative temperature coefficient, meaning it decreases as the junction temperature increases, which is a characteristic of Schottky diodes.

- Reverse Current (IR):Maximum 40 µA at 520V, 25°C. Even under high reverse voltage and high temperature (maximum 20 µA at 175°C), its leakage current is extremely low, thereby minimizing off-state losses.

- Total Capacitance Charge (QC):Thamani ya kawaida ni 12 nC kwenye 400V. Hii ni kipimo muhimu cha ubora kinachopima utendaji wa swichi. QC ya chini inamaanisha malipo machache yanayohitaji kusogezwa kwa kila mzunguko wa swichi, na hivyo kupunguza upotevu wa nguvu wa swichi na kusaidia uendeshaji wa masafa ya juu zaidi.

2.2 Maximum Ratings and Thermal Characteristics

Vigezo hivi hufafanua mipaka kamili ya uendeshaji salama na uwezo wa kudhibiti joto wa kifaa.

- Surge Non-Repetitive Forward Current (IFSM):14.4A for a 10ms half-sine wave. This rating is crucial for withstanding short-circuit events, inrush currents, or other transient overload conditions.

- Junction Temperature (TJ):Maximum 175°C. The higher maximum operating temperature is a direct advantage of silicon carbide material, allowing operation in harsh environments or enabling more compact designs with higher power density.

- Thermal Resistance, Junction to Case (RθJC):Typical value is 3.7 °C/W. A lower thermal resistance indicates high efficiency of heat transfer from the semiconductor junction to the package case. This is a key parameter for thermal management design, as it determines how much the junction temperature will rise for a given power dissipation. A lower RθJC allows for higher power handling capability or the use of smaller heat sinks.

- Total Power Dissipation (PD):40W. Hii ndiyo nguvu ya juu zaidi ambayo kifaa kinaweza kutumia, imepunguzwa na upinzani wa joto na halijoto ya juu ya kiunganishi.

3. Uchambuzi wa Mviringo wa Utendaji

Mwongozo wa maelezo una mikunjo mingi ya sifa muhimu kwa usanifu wa kina na uigizaji.

3.1 Forward Characteristics (VF-IF)

Mchoro huu unaonyesha uhusiano kati ya kushuka kwa voltage ya mbele na mkondo wa mbele katika halijoto tofauti za makutano. Wasanifu hutumia mchoro huu kuhesabu hasa upotezaji wa uendeshaji chini ya hali tofauti za uendeshaji. Safu ya mkunjo itaonyesha uhusiano wa kawaida wa kielelezo, ambapo kwa mkondo fulani, halijoto ya juu zaidi inasababisha kushuka kwa voltage ya chini.

3.2 Reverse Characteristics (VR-IR)

This curve illustrates the relationship between the reverse leakage current and the applied reverse voltage. It verifies the low leakage current specified in the table across the entire operating voltage range.

3.3 Capacitance Characteristics (VR-Ct)

This graph shows the variation of junction capacitance with reverse voltage. The capacitance decreases nonlinearly as the reverse voltage increases. This information is crucial for predicting switching behavior, as the stored charge is the integral of capacitance with respect to voltage. The decrease of capacitance with voltage is a favorable characteristic for high-voltage switching.

3.4 Surge Current Derating (IFSM – PW)

Sifa hii inaonyesha jinsi mkondo wa mshtuko unaoruhusiwa unavyopungua kadri upana wa pigo unavyoongezeka. Inatoa mwongozo kwa kubuni saketi ya ulinzi au kutathmini uwezo wa kustahimili hali ya hitilafu inayozidi kiwango cha kawaida cha ms 10.

3.5 Transient Thermal Impedance (ZθJC)

Mkunjo huu ni muhimu sana kwa kutathmini utendaji wa joto chini ya hali ya nguvu ya pigo. Unaonyesha upinzani wa joto unaofaa kutoka kwa kiungo hadi kwenye kifurushi kwa pigo moja la muda tofauti. Kwa pigo fupi, upinzani wa joto ni chini sana kuliko RθJC ya hali thabiti, ikimaanisha kuwa kiungo kinaweza kustahimili nguvu ya papo hapo ya juu zaidi bila kupashwa joto kupita kiasi. Hii ni muhimu kwa matumizi yanayo na mkondo wa kilele cha juu.

4. Mechanical and Packaging Information

4.1 Package Outline and Dimensions

Kifaa hiki kinatumia ufungaji wa kiwango cha tasnia wa TO-252-3L wa kushikamana na uso. Vipimo muhimu katika hati ya maelezo ni pamoja na:

- Urefu wa mwili wa ufungaji (D): 6.10 mm (thamani ya kawaida)

- Upana wa mwili wa ufungaji (E): 6.60 mm (thamani ya kawaida)

- Total Height (H): 9.84 mm (Typ.)

- Lead Pitch (e1): 2.28 mm (Basic)

- Urefu wa Pini (L): 1.52 mm (Thamani ya Kawaida)

Inatoa mchoro wa kina wa mitambo ulio na thamani zote muhimu za chini kabisa, za kawaida na za juu kabisa, ili kuhakikisha muundo sahihi wa PCB pad na nafasi ya usakinishaji.

4.2 Pin Configuration and Polarity

The TO-252-3L package has three connection points: two pins and an exposed metal heat sink.

- Pin 1:Cathode (K)

- Pin 2:Anode (A)

- Case (Heat Sink):Connect to Cathode (K)

Important Note:The enclosure is electrically connected to the cathode. This must be considered in the PCB layout to prevent accidental short circuits. The heat sink is the primary thermal path and must be soldered to a copper pad of adequate size on the PCB.

4.3 Recommended PCB Land Pattern

It includes the recommended surface mount pad layout. This layout is optimized for solder joint reliability and thermal performance. It typically consists of a large central pad for the thermal slug to maximize heat transfer to the PCB copper layers, and two smaller pads for the anode and cathode leads. Following this recommendation helps in forming proper solder fillets and minimizing thermal stress.

5. Mwongozo wa Uchomaji na Usanikishaji

Ingawa dondoo hili halielezi kwa kina mkunjo maalum wa uchomeaji wa reflow, mwongozo wa jumla unaotumika kwa vifaa vya usakinishaji wa uso vya kifurushi cha TO-252 bado unatumika.

- Uchomeaji wa Reflow:Kwa kawaida inafaa kutumia mkunjo wa kawaida wa kulehemu bila risasi wenye kiwango cha juu cha joto kisichozidi 260°C. Uwezo mkubwa wa joto wa kibao cha kutuliza joto kunaweza kuhitaji marekebisho makini ya mkunjo ili kuhakikisha kuwa pointi zote za kulehemu zinafikia joto linalofaa la kuyeyusha.

- Uendeshaji:Kanuni za kawaida za kuzuia utokaji umeme wa tuli zinapaswa kufuatwa, kama ilivyo kwa vifaa vyote vya semiconductor.

- Uhifadhi:Kifaa kinapaswa kuhifadhiwa katika mazingira yaliyokauka na yaliyodhibitiwa. Anuwai ya halijoto ya uhifadhi iliyobainishwa ni -55°C hadi +175°C.

6. Mapendekezo ya Utumizi

6.1 Saketi ya Kawaida ya Utumizi

- Boost Diode in PFC Stage:Its fast switching and low QC characteristics minimize switching losses at high frequencies, thereby improving PFC efficiency. The high VRRM is suitable for universal input designs.

- Output Rectifier in LLC Resonant Converter:Sifa ya kurejesha sifuri inaondoa hasara ya kurejesha nyuma, ambayo ni faida kuu katika topolojia ya resonant ya masafa ya juu, ikiruhusu uendeshaji wa joto la chini na ufanisi wa juu zaidi.

- Diode ya kudumu ya mtiririko/ya kukaza katika kudhibiti motor na inverter:Inatumiwa sambamba na MOSFET au IGBT ya kubadili, kutoa njia ya mkondo wa mzigo wa hisia. Kubadili haraka huzuia vipeo vya voltage na kupunguza mkazo wa kubadili kuu.

- Solar Microinverters and String Inverters:Benefiting from their high efficiency and high-temperature operation capability in outdoor environments.

- High-Density AC/DC and DC/DC Converters:Mchanganyiko wa uwezo wa masafa ya juu na viwango vya joto vya juu huruhusu matumizi ya vipengele vya sumaku na vichungi vya joto vidogo zaidi, na hivyo kuongeza msongamano wa nguvu.

6.2 Design Considerations

- Thermal Management:Ingawa RθJC yake ni ya chini, upoaji joto unaofaa ni muhimu sana. Pedi ya PCB ya heatsink lazima iunganishwe na ndege kubwa ya shaba au heatsink ya nje, ili kutumia kikamilifu viwango vyake vya sasa na nguvu. Vias za upoaji joto chini ya pedi husaidia kuhamisha joto kwa tabaka za ndani au chini.

- Vifaa vilivyounganishwa sambamba:Spec inataja faida ya "hakuna kukimbia kwa joto kwa vifaa vilivyounganishwa sambamba". Hii inatokana na mgawo chanya wa joto wa voltage ya mbele ya diode ya Schottky ya Silikoni Kabidi. Wakati kifaa kimoja kinapokuwa na joto zaidi, VF yake huongezeka kidogo, na kusababisha usambazaji sare zaidi wa sasa kwa vifaa vya sambamba vilivyo baridi, na hivyo kuchochea usambazaji thabiti wa sasa.

- Saketi ya buffer:Although the diode itself is very fast, circuit parasitic parameters can still cause voltage overshoot during turn-off. In some high di/dt applications, a snubber circuit may be required to clamp these spikes and protect the diode and other components.

- Gate Drive Considerations:The fast switching of this diode can lead to high di/dt and dv/dt. This may require attention to the gate drive design of the accompanying MOSFET/IGBT to avoid issues such as false triggering due to the Miller effect.

7. Technical Comparison and Advantages

Ikilinganishwa na diodi ya kurejesha haraka ya silikoni ya kawaida hata diodi ya mwili ya MOSFET ya silikoni kaboni, diodi hii ya Schottky ya silikoni kaboni ina faida kubwa:

- Sifuri ya mkondo wa kurejesha nyuma:Hii ndio faida yake kuu zaidi ikilinganishwa na diodi ya silicon PN. Inaondoa kabisa upotezaji wa urejeshaji wa kinyume na kelele zinazohusiana za kubadili, na hivyo kufanikisha ufanisi na mzunguko wa juu zaidi.

- Shinikizo la Mbele la Chini Zaidi Kuliko Diodi za Kwanza za Silikoni Kabati:Diodi za kisasa za Schottky za Silikoni Kabati zimepunguza kwa kiasi kikubwa VF, na hivyo kupunguza tofauti na diodi za silicon huku zikiendelea kubeba faida zote za kasi ya juu na joto la juu.

- Higher Operating Temperature:Maximum junction temperature of 175°C, compared to typically 150°C for silicon devices, providing greater design margin and reliability in high-temperature environments.

- Excellent Surge Capability:Ina na ukubwa wake, ina kiwango cha IFSM kinachofaa, ikitoa uthabiti.

- Ikilinganishwa na diodi ya mwili ya MOSFET ya Silikoni Kaboni:Ingawa diodi ya mwili ya MOSFET ya Silikoni Kaboni pia ni diodi ya PIN yenye sifa duni ya kurejesha kinyume, katika saketi ngumu za kubadili, kwa kawaida hupendelewa kutumia diodi tofauti ya Schottky ya Silikoni Kaboni kama diodi ya kudumisha mtiririko, ili kuepuka hasara za diodi ya mwili.

8. Maswali Yanayoulizwa Mara kwa Mara

Swali: "Zero Reverse Recovery" inamaanisha nini kwa muundo wangu kwa vitendo?

Jibu: Hii inamaanisha unaweza kupuuza hasara za urejesho wa nyuma unapokokotoa ufanisi. Pia hurahisisha muundo wa saketi ya buffer na hupunguza usumbufu wa sumakuumeme unaotokana wakati diode inapozimwa.

Swali: Kifuniko kimeunganishwa kwenye cathode. Nikihitaji kutengwa, nifanyeje?

Jibu: Kutenganisha kwa umeni kunahitaji matumizi ya pedi ya joto ya maboksi kati ya fin ya kupoeza diode na kipoezi, pamoja na podi ya bega ya maboksi. Hii inaongeza upinzani wa joto, kwa hivyo ni lazima kuhesabu usawazishaji.

Swali: Naweza kutumia sasa yake kamili ya 8A kwa mfululizo?

Jibu: Unaweza tu ikiwa unaweza kudumisha joto la kifurushi kwenye 135°C au chini. Ikiwa muundo wa joto unasababisha joto la kifurushi kuwa juu zaidi, sasa halisi ya mfululizo itapungua. Tumia upotezaji wa nguvu na upinzani wa joto kuhesabu upotezaji wa nguvu unaoruhusiwa wa kiwango cha juu chini ya hali maalum za kipoezi na mazingira, kisha toa sasa kutoka kwa mkunjo wa VF.

Swali: Kwa nini vigezo vya QC ni muhimu?

Jibu: QC inawakilisha nishati iliyohifadhiwa kwenye uwezo wa makutano ya diode. Katika mzunguko, wakati wa kuwasha transistor, malipo haya lazima yaondolewe, na kusababisha mwinuko wa mkondo. QC ya chini hupunguza mwinuko huu, na hivyo kupunguza hasara za kubadili kwa transistor ya udhibiti na kupunguza mkazo kwenye vipengele vyote viwili.

9. Uchambuzi wa Kesi ya Uundaji Halisi

Scenario:Design a 500W server power supply that complies with the 80Plus Titanium efficiency standard. Its PFC stage employs a bridgeless totem-pole topology and operates at a frequency of 100 kHz.

Challenge:Traditional silicon ultrafast diodes exhibit significant reverse recovery losses at the 100 kHz PFC boost position, limiting efficiency and causing thermal management issues.

Solution:Adopt a 650V silicon carbide Schottky diode as the boost diode.

Implementation and Results:

1. Place the diode in the standard boost diode position.

2. Due to its zero reverse recovery characteristic, the switching-off loss is almost eliminated.

3. Low Qc reduces the conduction loss of the complementary MOSFET.

4. A rated temperature of up to 175°C allows it to be placed close to other heat-generating components.

. Kwa sababu ya kutokuwa na urejeshaji wa sifuri, hasara ya kubadili wakati wa kuzima imepunguzwa karibu kabisa.

. The low Qc reduces the turn-on loss of the complementary MOSFET.

. Ukadiraji wa juu wa 175°C unaruhusu kuwekwa karibu na vipengele vingine vya moto.

5. Matokeo:Ikilinganishwa na suluhisho bora la mbadala la silikoni, ufanisi uliopimwa wa kiwango cha PFC kwenye mzigo kamili uliboreshwa kwa takriban 0.7%. Hii inachangia moja kwa moja kukidhi viwango vikali vya ufanisi vya Titanium. Zaidi ya hayo, diode inafanya kazi kwa joto la chini, kuruhusu mpangilio mwembamba zaidi au kupunguza mahitaji ya mtiririko wa hewa, na hivyo kuongeza msongamano wa nguvu.

10. Kanuni ya Uendeshaji

Diodi ya Schottky huundwa na kiunganishi cha chuma-semiconductor, tofauti na diodi ya kawaida ya PN inayotumia kiunganishi cha semiconductor-semiconductor. Katika diodi ya Schottky ya Silikoni Kaboni, semiconductor ni Silikoni Kaboni. Kiunganishi cha chuma-SiC huunda kizuizi cha Schottky, kinachoruhusu tu vibebaji wengi wa chaji kufanya umeme. Hii inatofautiana na diodi ya PN inayohusisha vibebaji wengi na wachache wa chaji.

Ukosefu wa kuingizwa na uhifadhi wa vibebaji wachache wa chaji ndio sababu ya msingi ya ukosefu wa urejeshaji wa nyuma. Wakati voltage kwenye diodi ya Schottky inapogeuka kuwa ya nyuma, hakuna chaji ya vibebaji wachache waliohifadhiwa inayohitaji kusafishwa kutoka eneo la kuteleza; mara tu vibebaji wanapokwisha kutoka kwenye eneo la kiunganishi, mkondo hukoma karibu mara moja. Hii husababisha sifa ya "urejeshaji wa nyuma sifuri". Kubadilisha haraka ni matokeo ya moja kwa moja ya utaratibu huu wa upitishaji umeme wa unipolar.

11. Mwelekeo wa Teknolojia

Silicon carbide power devices are key enabling technologies for the trend towards higher efficiency, higher frequency, and higher power density in all areas of power electronics. The silicon carbide diode market is driven by the following factors:

- Electric Vehicles:Mahitaji ya vichaji vya ndani ya gari vinavyochaji kwa kasi zaidi, vibadilishaji DC-DC yenye ufanisi zaidi, na vibadilishaji vya mvutano vya kuvuta (traction inverters) vyenye mzunguko wa kubadili umeme wa juu zaidi.

- Nishati Inayoweza Kupanuliwa:Vibadilishaji vya umeme vya nishati ya jua na upepo hufaidika kutokana na ufanisi wa juu zaidi (kuongeza uzalishaji wa nishati) na uwezo wa joto la juu zaidi (kuboresha uaminifu wa usakinishaji wa nje).

- Data Center and Telecommunications:The pursuit of higher efficiency and greater rack power density necessitates the use of advanced components such as silicon carbide diodes in server power supplies and rectifiers.

- Industrial Motor Drives:Kutafuta kiwango cha juu cha udhibiti wa upana wa mawimbi na ufanisi.

Kwa hasa kuhusu mwelekeo wa diodi za Schottky za Silikoni Kaboni ni: kushuka kwa chini zaidi kwa voltage ya kuwashwa, msongamano wa juu zaidi wa mkondo, na kuimarisha uaminifu na kupunguza gharama kupitia ukubwa wa utengenezaji na ukomavu wa mchakato. Ujumuishaji na MOSFET za Silikoni Kaboni katika moduli ya chip nyingi pia ni mwelekeo unaokua.

Ufafanuzi wa kina wa istilahi za maelezo ya LED

Kamusi Kamili ya Istilahi za Teknolojia ya LED

I. Viashiria Muhimu vya Utendaji wa Kielektroniki na Mwanga

| Istilahi | Unit/Penunjukan | Penjelasan Populer | Kwa nini ni muhimu |

|---|---|---|---|

| Ufanisi wa Mwanga (Luminous Efficacy) | lm/W (lumens per watt) | The luminous flux emitted per watt of electrical power; the higher the value, the more energy-efficient. | Directly determines the energy efficiency rating and electricity cost of the luminaire. |

| Fluxi Mwangaza (Luminous Flux) | lm (lumen) | Jumla ya kiasi cha mwanga kinachotolewa na chanzo cha mwanga, kinachojulikana kwa kawaida kama "mwangaza". | Huamua ikiwa taa inatosha kuwa mkali. |

| Pembe ya kuona (Viewing Angle) | ° (degree), such as 120° | The angle at which light intensity drops to half, determining the beam width. | Affects the illumination range and uniformity. |

| Joto la rangi (CCT) | K (Kelvin), k.m. 2700K/6500K | Joto la rangi ya mwanga, thamani ya chini huelekea manjano/joto, thamani ya juu huelekea nyeupe/baridi. | Huamua mazingira ya taa na matumizi yanayofaa. |

| Kielelezo cha Uonyeshaji Rangi (CRI / Ra) | Unitless, 0–100 | The ability of a light source to reproduce the true colors of objects, with Ra≥80 being preferable. | Inaathiri usahihi wa rangi, hutumika katika maeneo yenye mahitaji makubwa kama vile maduka makubwa, majumba ya sanaa. |

| Tofauti ya uvumilivu wa rangi (SDCM) | Idadi ya hatua za duaradufu ya MacAdam, kama vile "5-step" | A quantitative indicator of color consistency; a smaller step number indicates better color consistency. | Ensure no color variation among luminaires from the same batch. |

| Wavelengthu Kuu (Dominant Wavelength) | nm (nanomita), k.m. 620nm (nyekundu) | Thamani ya wavelength inayolingana na rangi ya LED ya rangi. | Determines the hue of monochromatic LEDs such as red, yellow, and green. |

| Spectral Distribution | Wavelength vs. Intensity Curve | Shows the intensity distribution of light emitted by an LED across various wavelengths. | Affects color rendering and color quality. |

Vigezo vya Umeme

| Istilahi | Ishara | Penjelasan Populer | Vidokezo vya Ubunifu |

|---|---|---|---|

| Voltage ya Mbele (Forward Voltage) | Vf | Voltage ya chini inayohitajika kuwasha LED, kama "kizingiti cha kuanzisha". | Voltage ya chanzo cha umeme inahitaji kuwa ≥ Vf, voltage inajumlishwa wakati LED nyingi zimeunganishwa mfululizo. |

| Forward Current | If | The current value that enables the LED to emit light normally. | Inatumiwa kwa kawaida kuendesha mkondo wa kudumu, mkondo huamua mwangaza na maisha. |

| Mkondo wa juu zaidi wa msukumo (Pulse Current) | Ifp | Peak current that can be withstood for a short period, used for dimming or flashing. | Pulse width and duty cycle must be strictly controlled, otherwise overheating damage will occur. |

| Reverse Voltage | Vr | Upeo wa juu wa voltage ya nyuma ambayo LED inaweza kustahimili, ukizidi huo unaweza kusababisha kuvunjika. | Katika mzunguko, ni muhimu kuzuia uunganishaji wa kinyume au mshtuko wa voltage. |

| Thermal Resistance | Rth (°C/W) | Upinzani wa joto kutoka kwenye chip hadi kwenye sehemu ya kuuziwa, thamani ya chini inaonyesha usambazaji bora wa joto. | Upeo wa juu wa upinzani wa joto unahitaji muundo wa upoaji joto wenye nguvu zaidi, vinginevyo joto la kiungo litaongezeka. |

| Uvumilivu wa Utoaji Umeme wa Tuli (ESD Immunity) | V (HBM), kama vile 1000V | Uwezo wa kukabiliana na mshtuko wa umeme wa tuli, thamani ya juu zaidi ina maana ya uwezo mdogo wa kuharibika kwa umeme wa tuli. | Hatua za kinga dhidi ya umeme wa tuli zinahitajika katika uzalishaji, hasa kwa LED zenye usikivu mkubwa. |

III. Usimamizi wa Joto na Uaminifu

| Istilahi | Viashiria Muhimu | Penjelasan Populer | Athari |

|---|---|---|---|

| Joto la Kiungo (Junction Temperature) | Tj (°C) | Halisi ya joto la kufanya kazi ndani ya chip ya LED. | Kwa kila kupungua kwa 10°C, maisha yanaweza kuongezeka mara mbili; joto la juu sana husababisha kupungua kwa mwanga na kuhama kwa rangi. |

| Kupungua kwa mwanga (Lumen Depreciation) | L70 / L80 (saa) | Muda unaohitajika ili mwangaza upunguke hadi 70% au 80% ya thamani ya awali. | Define the "useful life" of an LED directly. |

| Lumen Maintenance | % (e.g., 70%) | Asilimia ya mwangaza uliobaki baada ya kutumia kwa muda fulani. | Inaonyesha uwezo wa kudumisha mwangaza baada ya matumizi ya muda mrefu. |

| Mabadiliko ya Rangi (Color Shift) | Δu′v′ au Ellipse ya MacAdam | Kiwango cha mabadiliko ya rangi wakati wa matumizi. | Inaathiri uthabiti wa rangi katika eneo la taa. |

| Thermal Aging | Kupungua kwa sifa za nyenzo. | Uharibifu wa nyenzo za ufungaji unaosababishwa na joto la juu la muda mrefu. | Inaweza kusababisha kupungua kwa mwangaza, mabadiliko ya rangi, au kushindwa kwa mzunguko wazi. |

Nne. Ufungaji na Nyenzo

| Istilahi | Aina za Kawaida | Penjelasan Populer | Sifa na Matumizi |

|---|---|---|---|

| Aina ya Ufungaji | EMC, PPA, Ceramic | A housing material that protects the chip and provides optical and thermal interfaces. | EMC offers good heat resistance and low cost; ceramic provides superior heat dissipation and long lifespan. |

| Chip Architecture | Face-up, Flip Chip | Chip Electrode Layout. | Flip-chip offers better heat dissipation and higher luminous efficacy, suitable for high-power applications. |

| Phosphor coating | YAG, silicates, nitrides | Inapakuliwa kwenye chipi ya mwanga wa bluu, sehemu hubadilishwa kuwa njano/nyekundu, na kuchanganywa kuwa mwanga mweupe. | Fosfori tofauti huathiri ufanisi wa mwanga, halijoto ya rangi na ubora wa kuonyesha rangi. |

| Lens/Usanifu wa Optics | Uso wa gorofa, microlens, kutafakari kwa jumla | Optical structure on the encapsulation surface, controlling light distribution. | Determines the emission angle and light distribution curve. |

V. Quality Control and Binning

| Istilahi | Yaliyomo katika Uainishaji | Penjelasan Populer | Kusudi |

|---|---|---|---|

| Luminous flux binning | Codes such as 2G, 2H | Grouped by brightness level, each group has a minimum/maximum lumen value. | Ensure consistent brightness within the same batch of products. |

| Voltage binning | Codes such as 6W, 6X | Group by forward voltage range. | Facilitates matching with the driving power supply and improves system efficiency. |

| Kugawanya kwa makundi kulingana na rangi | 5-step MacAdam ellipse | Group by color coordinates to ensure colors fall within an extremely narrow range. | Ensure color consistency to avoid uneven color within the same luminaire. |

| Color temperature binning | 2700K, 3000K, n.k. | Pangilia kwa makundi kulingana na joto la rangi, kila kundi lina anuwai maalum ya kuratibu. | Inakidhi mahitaji ya joto la rangi katika mazingira tofauti. |

Sita, Uchunguzi na Uthibitishaji

| Istilahi | Kigezo/Uchunguzi | Penjelasan Populer | Meaning |

|---|---|---|---|

| LM-80 | Lumen Maintenance Test | Long-term operation under constant temperature conditions, recording luminance attenuation data. | Used for estimating LED lifetime (in conjunction with TM-21). |

| TM-21 | Lifetime projection standard | Kuhesabu maisha ya matumizi halisi kulingana na data ya LM-80. | Toa utabiri wa maisha wa kisayansi. |

| IESNA standard | Illuminating Engineering Society Standard | Covers optical, electrical, and thermal test methods. | Kigezo cha upimaji kinachokubalika kitaalamu. |

| RoHS / REACH | Udhibitisho wa usawa wa mazingira. | Hakikisha bidhaa hazina vitu hatari (kama risasi, zebaki). | Masharti ya kuingia kwenye soko la kimataifa. |

| ENERGY STAR / DLC | Energy Efficiency Certification | Energy efficiency and performance certification for lighting products. | Inatumika kwa mara nyingi katika ununuzi wa serikali na miradi ya ruzuku, kuimarisha ushindani wa soko. |