Table of Contents

- 1. Product Overview

- 1.1 Core Features and Target Applications

- 2. Viwango vya Kiufundi na Ufafanuzi wa Kina

- 2.1 Viwango vya Juu Kabisa

- 2.2 Electro-Optical Characteristics

- 3. Uchambuzi wa Mkunjo wa Utendaji

- 3.1 Sakiti ya Kujaribu Muda wa Kuwasha/Kuzima

- 4. Habari ya Mitambo na Ufungashaji

- 4.1 Usanidi wa Pini na Mchoro wa Kanuni

- 4.2 Package Dimensions and Options

- 4.3 Device Marking

- 5. Soldering and Assembly Guide

- 5.1 Masharti ya Uchimbaji

- 6. Taarifa za Ufungaji na Maagizo

- 6.1 Ordering Part Number Structure

- 6.2 Packaging Quantity

- 6.3 Tape and Reel Specification

- 7. Application Notes and Design Considerations

- 8. Technical Comparison and FAQs

- 8.1 Tofauti na Vichanganyaji vya Mwanga Vingine

- 8.2 Maswali Yanayoulizwa Mara kwa Mara (Kulingana na Vigezo)

- 9. Kanuni ya Uendeshaji na Mielekeo

- 9.1 Basic Working Principle

- 9.2 Industry Trends

1. Product Overview

Familia ya EL827 ni mkusanyiko wa viunganishi vya mwanga (optocouplers) kulingana na fototransistors, na hutumia kifurushi cha kawaida cha tasnia cha pini 8 cha kuingiza safu mbili (DIP). Vifaa hivi vimeundwa kutoa utengano wa umeme na usafirishaji wa ishara kati ya saketi zinazofanya kazi kwenye uwezo tofauti au upinzani. Kazi yao ya msingi inafanywa kupitia kuunganishwa kwa mwanga kati ya diode inayotoa mionzi ya infrared (IRED) na kigunduzi cha fototransistor cha silikoni. Usanidi huu huruhusu ishara ya udhibiti kupitishwa kutoka kwenye mlango wa kuingiza hadi kwenye mlango wa kutoka, huku ukidumisha kiwango cha juu cha utengano wa umeme, ambacho ni muhimu kwa usalama na upinzani wa kelele katika mifumo mingi ya elektroniki.

Faida kuu ya familia hii ni mchanganyiko wa uwiano wa juu wa uhamishaji wa sasa (CTR) na viwango thabiti vya voltage ya utengano. Kifurushi cha DIP cha kompakt kinatoa chaguzi nyingi za umbo la pini, zikiwamo aina ya kawaida, aina yenye nafasi pana ya pini, na aina ya kufungwa kwenye uso, hivyo kutoa urahisi kwa michakato tofauti ya usanikishaji wa PCB. Kifaa hiki kinakidhi viwango kuu vya kimataifa vya usalama na mazingira, na kinafaa kwa matumizi mapana ya kimataifa.

1.1 Core Features and Target Applications

Mfululizo wa EL827 umeundwa na sifa muhimu kadhaa zinazobainisha anuwai ya utendaji na ufaafu wake wa matumizi. Uwiano wa Uhamishaji wa Umeme (CTR) unachukua anuwai kutoka 50% hadi 600% (chini ya hali ya IF=5mA, VCE=5V), na kuhakikisha uhamishaji wa ishara wenye ufanisi na unyeti mzuri. Kiasi cha voltage ya kutengwa kati ya sehemu za kuingiza na kutoka ni Vrms 5000, ikitoa kizuizi kikali dhidi ya mabadiliko ya ghafla ya voltage ya juu na kuimarisha usalama wa mfumo.

Bidhaa hii inalingana na kanuni za RoHS na REACH za Umoja wa Ulaya. Imepata uthibitisho wa usalama kutoka kwa taasisi kadhaa maarufu za kimataifa, zikiwemo UL, cUL (faili namba E214129), VDE (faili namba 132249), SEMKO, NEMKO, DEMKO, FIMKO, na CQC. Uthibitisho huu ni muhimu sana kwa bidhaa zinazouzwa katika soko zenye mahitaji madhubuti ya usalama.

Matumizi ya kawaida ya mfululizo wa EL827 ni pamoja na:

- Programmable Logic Controller (PLC) na mifumo ya otomatiki ya viwanda.

- Vifaa vya mfumo vinavyohitaji ukusanyaji wa ishara bila kelele na vyombo vya usahihi vya kupima.

- Vifaa vya mawasiliano vinavyotumika kwa kutenganisha ishara na kulinda viunganishi.

- Vifaa vya nyumbani, kama vile jokofu na mifumo mingine ya udhibiti.

- Uhamishaji wa ishara wa jumla kati ya nyaya zenye uwezo tofauti na upinzani, kama kipengele cha msingi cha kutengwa.

2. Viwango vya Kiufundi na Ufafanuzi wa Kina

Sehemu hii inachambua kwa undani vigezo vya umeme na vya nuru vya kifaa. Kuelewa vipimo hivi ni muhimu kwa usanifu sahihi wa saketi na kuhakikisha uendeshaji thabiti wa muda mrefu.

2.1 Viwango vya Juu Kabisa

Viwango vya Juu Kabisa vinafafanua mipaka ya mkazo ambayo inaweza kusababisha uharibifu wa kudumu wa kifaa. Uendeshaji ndani ya au zaidi ya mipaka hii hauhakikishiwi na unapaswa kuepukwa katika matumizi ya kawaida. Viwango hivi vinabainishwa kwa joto la mazingira (Ta) la 25°C.

- Upande wa Ingizo (Diode):Mkondo endelevu wa mbele (IF) usizidi 60 mA. Mkondo mfupi wa kilele wa mbele (IFP) wa 1 A kwa mikrosekunde 1 unaruhusiwa. Voltage ya juu ya nyuma (VR) inayotumika kwenye diode ni 6 V. Matumizi ya nguvu (PD) upande wa ingizo yamewekwa kikomo cha 100 mW.

- Upande wa Pato (Transistor):Maximum collector current (IC) is 50 mA. Collector-emitter voltage (VCEO) can be up to 80 V, while emitter-collector voltage (VECO) is limited to 7 V. Output power dissipation (PC) is 150 mW.

- Device total parameters and environmental parameters:Total device power dissipation (PTOT) is 200 mW. Isolation voltage (VISO) between input and output sections is 5000 Vrms (tested for 1 minute at 40-60% relative humidity). Operating temperature range (TOPR) is -55°C to +110°C, storage temperature (TSTG) range is -55°C to +125°C. During assembly, soldering temperature (TSOL) must not exceed 260°C for 10 seconds.

2.2 Electro-Optical Characteristics

Vigezo hivi vinabainisha utendakazi wa kifaa chini ya hali za kawaida za uendeshaji, kwa kawaida hupimwa wakati Ta=25°C. Vina umuhimu mkwa katika kuhesabu utendakazi wa saketi.

Tabia za Ingizo (Infrared Emitting Diode):

- Voltage ya Mbele (VF):Thamani ya kawaida ni 1.2V, na upeo wa 1.4V wakati sasa ya mbele (IF) ya 20 mA inatumika. Kigezo hiki kinatumika kubainisha ukubwa wa upinzani wa kuzuia sasa upande wa ingizo.

- Sasa ya Kinyume (IR):Maximum 10 µA when a reverse voltage (VR) of 4V is applied, indicating the leakage current of the diode in the off state.

- Input capacitance (Cin):Typical value is 30 pF, maximum is 250 pF (measured at 0V, 1 kHz). This affects high-frequency switching performance.

Output Characteristics (Phototransistor):

- Collector-Emitter Dark Current (ICEO):The maximum value is 100 nA when VCE=20V and IF=0mA. This is the dark current of the phototransistor.

- Breakdown voltage:Collector-Emitter Breakdown Voltage (BVCEO) is minimum 80V (IC=0.1mA). Emitter-Collector Breakdown Voltage (BVECO) is minimum 7V (IE=0.1mA).

Transfer Characteristics (Coupling Performance):

- Uwiano wa Uhamishaji wa Umeme (CTR):Hii ni kigezo muhimu, kinachofafanuliwa kama (IC / IF) * 100%. Kwa mfululizo wa EL827, chini ya hali ya kawaida ya majaribio ya IF=5mA na VCE=5V, anuwai yake ni kutoka kiwango cha chini cha 50% hadi kiwango cha juu cha 600%. Anuwai hii pana inaweza kuashiria viwango tofauti au usambazaji wa uzalishaji. Mbuni lazima azingatie CTR ya chini kabisa, ili kuhakikisha transistor ya pato inaweza kujaa kwa kawaida.

- Collector-Emitter Saturation Voltage (VCE(sat)):The typical value is 0.1V, with a maximum of 0.2V when IF=20mA and IC=1mA. For output switching applications, a low VCE(sat) is desirable to minimize voltage drop.

- Isolation Resistance (RIO):When a DC voltage of 500V is applied between the isolation sides, the minimum value is 5 x 10^10 Ω. This indicates excellent DC isolation performance.

- Floating Capacitance (CIO):The typical value is 0.6 pF, and the maximum is 1.0 pF (VIO=0V, f=1MHz). This small capacitance contributes to achieving high common-mode transient immunity.

- Cutoff Frequency (fc):Typical value is 80 kHz (VCE=5V, IC=2mA, RL=100Ω, -3dB point). This defines the small-signal bandwidth of the device.

- Switching Time:Under specified test conditions (VCE=2V, IC=2mA, RL=100Ω), the rise time (tr) is typically 3 µs (max 18 µs), and the fall time (tf) is typically 4 µs (max 18 µs). These times determine the maximum digital switching speed.

3. Uchambuzi wa Mkunjo wa Utendaji

Mwongozo wa data unarejelea mikunjo ya kawaida ya sifa za kielektroniki-nyota. Ingawa michoro maalum haijarudiwa katika maandishi yaliyotolewa, lengo lake ni kuonyesha jinsi vigezo muhimu vinavyobadilika kulingana na hali ya uendeshaji. Wasanifu wanapaswa kukagua mwongozo kamili wa data kupata michoro hii.

Mikunjo ya kawaida inajumuisha:

- CTR dhidi ya sasa ya mwelekeo mzuri (IF):Inaonyesha jinsi uwiano wa usafirishaji wa sasa unavyobadilika kulingana na sasa ya pembejeo ya diode. CTR kwa kawaida hufikia kilele katika IF maalum na inaweza kupungua kwa sasa kubwa sana kutokana na joto au athari nyingine.

- CTR vs. Ambient Temperature (Ta):Illustrates the temperature dependence of the coupling efficiency. CTR typically decreases as temperature increases.

- Output Current (IC) vs. Collector-Emitter Voltage (VCE):Familia ya curves yenye IF kama parameta, inafanana na sifa za pato la transistor ya kawaida. Hii inaonyesha maeneo ya uendeshaji (eneo la kujaa, eneo la kukuza).

- Voltage ya kujaa (VCE(sat)) dhidi ya mkondo wa mbele (IF):Inaonyesha uhusiano kati ya uendeshaji wa pembejeo na kujaa kwa transistor ya pato.

3.1 Sakiti ya Kujaribu Muda wa Kuwasha/Kuzima

Mchoro 10 kwenye karatasi ya data unaelezea kwa kina mzunguko wa kawaida wa kupima na ufafanuzi wa umbo la wimbi linalotumika kupima wakati wa kubadili (ton, toff, tr, tf). Upimaji unafanywa kwa kutumia mkondo wa pembejeo wa msukumo kudhibiti IRED. Pato hufuatiliwa kupitia upinzani wa mzigo (RL) uliounganishwa kati ya kolekta na voltage ya usambazaji (VCC). Wakati wa kupanda (tr) hupimwa kutoka 10% hadi 90% ya thamani ya mwisho ya msukumo wa pato, na wakati wa kushuka (tf) hupimwa kutoka 90% hadi 10%. Kuelewa usanidi huu wa upimaji husaidia wabunifu kurudisha hali hizo wanapohitaji kuonyesha utendaji wa kifaa katika mzunguko wao maalum wa utumizi.

4. Habari ya Mitambo na Ufungashaji

EL827 inapatikana kwa kifurushi cha 8-pin DIP, ikitoa chaguo mbalimbali za umbo la pini ili kukidhi muundo tofauti wa PCB na mbinu za usanikishaji.

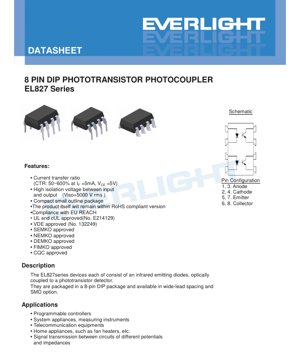

4.1 Usanidi wa Pini na Mchoro wa Kanuni

Mchoro wa ndani wa kanuni unaonyesha diode inayotoa miale ya infrared imeunganishwa kati ya pini 1/3 (anodi) na 2/4 (kathodi). Emita ya transistor nyeti-kwa-mwanga imeunganishwa kwa pini 5/7, na kolekta yake imeunganishwa kwa pini 6/8. Pini zenye utendakazi sawa zimeunganishwa ndani ili kutoa nguvu ya mitambo na kwa uwezekano kupunguza inductance ya pini. Unganisho la kawaida ni kutumia pini moja kutoka kila jozi.

Mgawo wa Pini:

- Pini 1, 3: Anodi (A)

- Pin 2, 4: Cathode (K)

- Pin 5, 7: Emitter (E)

- Pini 6, 8: Collector (C)

4.2 Package Dimensions and Options

Detailed mechanical drawings are provided for each package variant:

- Standard DIP type:Traditional through-hole package.

- M option type:Features "wide pin bending", providing a pin pitch of 0.4 inches (approximately 10.16mm), which may be suitable for breadboards or specific layout requirements.

- S option type:Surface mount pin form for reflow soldering.

- S1 option type:A "low-profile" surface-mount lead form, which may offer a lower standoff height compared to the S option.

The datasheet also includes recommended pad layouts for the surface-mount options (S and S1), which are crucial for achieving reliable solder joints and proper mechanical alignment during the reflow soldering process.

4.3 Device Marking

The device top is marked with "EL827" to denote the series, followed by a one-digit year code (Y), a two-digit week code (WW), and an optional "V" suffix if the unit is VDE-approved. This marking allows for tracing the production date and variant.

5. Soldering and Assembly Guide

5.1 Masharti ya Uchimbaji

Mwongozo wa Data hutoa maelezo muhimu kwa mchakato wa usanikishaji, hasa kwa lahaja ya kukatwa kwenye uso. Joto la juu la mwili linaloruhusiwa wakati wa kuchimbia limefafanuliwa na mkunjo wa kuyeyusha unaorejelea IPC/JEDEC J-STD-020D. Vigezo muhimu vya mkunjo huu ni pamoja na:

- Joto la kukausha:Kiwango cha chini (Tsmin) 150°C, kiwango cha juu (Tsmax) 200°C.

- Muda wa kukausha:Curve inaonyesha muda maalum (ts) ndani ya safu hii ya joto, kupasha joto kwa taratibu kipengele na bodi ya mzunguko, kupunguza kiwango cha mshtuko wa joto.

- Kiwango cha juu cha joto dhidi ya wakati:Curve haipaswi kuzidi kiwango cha juu cha joto cha kuunganisha (TSOL) cha 260°C, na muda wa kuwa juu ya 260°C unapaswa kuwa mdogo (kwa kawaida kama ilivyoelezwa katika viwango vya juu kabisa, kufungwa hadi sekunde 10).

Kufuata curve hii ni muhimu ili kuzuia uharibifu wa kifuniko cha plastiki, ufungaji wa waya wa ndani, au chip ya semiconductor yenyewe. Kwa vipengele vya kupenya kwenye shimo, kuunganishwa kwa wimbi la solder au kuunganishwa kwa mkono pia kunapaswa kuzingatia kikomo cha 260°C, sekunde 10.

6. Taarifa za Ufungaji na Maagizo

6.1 Ordering Part Number Structure

Part number follows the format: EL827X(Z)-V

- X:Lead form options: None (Standard DIP), M (Wide lead bend), S (Surface mount), S1 (Low-profile surface mount).

- Z:Tape and reel packaging options: None (tube), TA, or TB (different tape feed directions).

- V:Alama ya hiari ya uthibitisho wa usalama wa VDE.

6.2 Packaging Quantity

- Chaguo za kawaida za DIP na M: 45 kwa kila mrija.

- S(TA), S(TB), S1(TA), S1(TB) options: 1000 pieces per reel.

6.3 Tape and Reel Specification

Detailed carrier tape dimensions are provided for the S and S1 options (TA and TB). Parameters include pocket dimensions (A, B, Do, D1), tape pitch (Po, P1), tape thickness (t), and overall tape width (W). Options TA and TB differ in the tape feed direction and must be configured correctly in the pick-and-place machine. The diagram shows the orientation of the device within the tape pocket.

7. Application Notes and Design Considerations

Several factors must be considered when designing with the EL827 optocoupler to ensure optimal performance and reliability.

Input Circuit Design:A current-limiting resistor must be connected in series with the input IRED. Its resistance is calculated based on the supply voltage (Vcc_in), the required forward current (IF), and the diode's forward voltage drop (VF): R_in = (Vcc_in - VF) / IF. The chosen IF affects CTR, switching speed, and device lifetime. It is recommended to operate at or below the recommended continuous operating current of 20mA.

Output Circuit Design:Phototransistors can be used in switching (saturation) mode or linear (amplification) mode. For digital switching, a pull-up resistor (RL) is connected between the collector and the output-side supply voltage (Vcc_out). The value of RL affects the switching speed (lower RL is faster, but higher IC) and current consumption. Ensure the output current (IC) does not exceed the maximum of 50mA. For linear applications, the device operates in its active region, but the non-linearity and temperature dependence of the CTR must be carefully considered.

Isolation and Layout:To maintain a high isolation rating, ensure sufficient creepage distance and electrical clearance between the copper traces on the input and output sides of the PCB according to relevant safety standards (e.g., IEC 60950-1, IEC 62368-1). Place the optocoupler in the layout so that it straddles the isolation barrier.

Bypassing and Noise:For noise-sensitive applications or to improve the stability of switching circuits, consider placing a small bypass capacitor (e.g., 0.1 µF) near the power supply pins on the input and output sides of the device.

8. Technical Comparison and FAQs

8.1 Tofauti na Vichanganyaji vya Mwanga Vingine

Tofauti kuu za EL827 ni voltage yake ya juu ya kutengwa ya 5000Vrms na anuwai pana ya CTR (50-600%). Ikilinganishwa na coupler mwanga wa msingi wa pini 4, DIP ya pini 8 hutoa pini mbili kwa kila terminal, ambayo inaweza kuboresha nguvu ya kufunga mitambo ya bodi na kutoa utendaji bora kidogo wa joto. Upatikanaji wa chaguo za kusakinisha kwenye uso (S, S1) na pini pana (M) hutoa kubadilika zaidi kuliko bidhaa nyingi za kifurushi kimoja. Uthibitisho kamili wa usalama wa kimataifa (UL, VDE, n.k.) ni faida dhahiri kwa bidhaa za kibiashara na viwanda zinazohitaji uthibitisho.

8.2 Maswali Yanayoulizwa Mara kwa Mara (Kulingana na Vigezo)

Swali: Inamaanisha nini kwa muundo wangu anuwai ya CTR ya 50-600%?

Jibu: Hii inaonyesha tofauti katika uzalishaji. Lazima uundie saketi yako ili iweze kufanya kazi kwa uaminifu naKiwango cha chiniThe guaranteed CTR (50% in this case) works to ensure the output switches properly under all conditions. If your design requires a specific sensitivity, you may need to select a device based on the measured CTR (binning) or use a circuit that can compensate for this variation.

Q: Can I use it for analog signal isolation?

A: While possible (using it in linear mode), it is not ideal due to the nonlinearity of CTR versus IF and its strong temperature dependence. For precision analog isolation, dedicated linear optocouplers or isolation amplifiers are recommended.

Q: How to choose between the S and S1 surface mount options?

Jibu: Chaguo la S1 "lililoinama" limeundwa kwa matumizi ambayo kukusanyika kwa PCB kuna vikwazo vikali vya urefu. Tafadhali angalia mchoro wa vipimo vya kifurushi kwenye mwongozo wa data, ulinganishe urefu wa kutoka kwenye bodi na vipimo vya jumla. Sifa za umeme ni sawa.

Swali: Muda wa kubadili unaonekana kuwa mwepesi (hadi 18µs). Je, hii inafaa kwa mawasiliano yangu ya haraka ya dijiti?

Jibu: Kwa kutengwa kwa kawaida kwa I/O ya dijiti katika kiunganishi cha PLC au kidhibiti kidogo, kasi hizi kwa kawaida zinatosha. Kwa mawasiliano ya haraka ya mfululizo (k.m., USB, kutengwa kwa RS-485), inapaswa kuzingatiwa kutengwa kwa haraka zaidi kwa dijiti (kulingana na uunganisho wa capacitance au sumaku) au mwongozo wa mwanga wa haraka ulioundwa mahsusi kwa viwango vya data vya anuwai ya Mbps.

9. Kanuni ya Uendeshaji na Mielekeo

9.1 Basic Working Principle

An optocoupler works by converting an electrical signal into light, transmitting that light across an electrically insulating gap, and then converting the light back into an electrical signal. In the EL827, current applied to the input infrared emitting diode (IRED) causes it to emit photons (light) at infrared wavelengths. This light passes through the transparent insulating molding compound and strikes the base region of the silicon phototransistor on the output side. The incident light generates electron-hole pairs in the base region, effectively acting as base current, thereby allowing a larger collector current to flow. This collector current is proportional to the incident light intensity, which in turn is proportional to the input diode current, establishing the Current Transfer Ratio (CTR). The key point is that the only connection between input and output is the light beam, thereby providing electrical isolation.

9.2 Industry Trends

Soko la optocoupler linaendelea kukua. Mienendo mikuu inajumuisha kukuza viwango vya juu vya data ili kukabiliana na itifaki za mawasiliano za viwanda za haraka na udhibiti wa nguvu wa dijiti. Mahitaji ya ushirikiano wa juu zaidi pia yanaongezeka, kwa mfano kuunganisha njia nyingi za kutengwa katika kifurushi kimoja, au kuunganisha utendaji wa ziada kama vile kiendeshi cha lango la IGBT/MOSFET. Zaidi ya hayo, mahitaji ya uaminifu wa juu zaidi, hasa katika matumizi ya magari na viwanda, yanasababisha uboreshaji wa utendaji katika joto la juu na uthabiti wa muda mrefu wa CTR. Ingawa optocoupler za jadi kama EL827 zenye msingi wa transistor ya tatu yenye usikivu wa mwanga bado ni nguzo ya msingi ya kutengwa kwa sababu ya unyenyekevu, ufanisi wa gharama, na uwezo wa voltage ya juu, teknolojia mpya kama vile visambaza kutengwa vya capacitive na magnetic (giant magnetoresistive) vinapata sehemu inayoongezeka katika matumizi yanayohitaji kasi kubwa sana, matumizi ya nguvu ya chini, na uwezo mkubwa wa kupinga kelele.

Detailed Explanation of LED Specification Terminology

Complete Explanation of LED Technical Terminology

I. Core Indicators of Photoelectric Performance

| Istilahi | Kipimo/Uwakilishi | Mafasiri ya Kawaida | Kwa Nini Ni Muhimu |

|---|---|---|---|

| Ufanisi wa Mwanga (Luminous Efficacy) | lm/W (lumen/watt) | Mwanga unaotolewa kwa kila watt ya umeme, unavyozidi kuwa mkubwa ndivyo unavyozidi kuokoa nishati. | Inaamua moja kwa moja kiwango cha ufanisi wa nishati na gharama ya umeme ya taa. |

| Mfumuko wa Mwanga (Luminous Flux) | lm (lumen) | Jumla ya mwanga unaotolewa na chanzo cha mwanga, unaojulikana kwa kawaida kama "mwangaza". | Huamua kama taa inatosha kuwa na mwangaza. |

| Pembe ya Kuona (Viewing Angle) | ° (digrii), k.m. 120° | Pembe ambapo nguvu ya mwanga hupungua hadi nusu, inayoamua upana wa boriti ya mwanga. | Huathiri eneo la mwangaza na usawa wake. |

| Joto la rangi (CCT) | K (Kelvin), kama 2700K/6500K | Joto la rangi ya mwanga, thamani ya chini inaelekea manjano/joto, thamani ya juu inaelekea nyeupe/baridi. | Huamua mazingira ya taa na matumizi yanayofaa. |

| Kielelezo cha Uonyeshaji Rangi (CRI / Ra) | Hakuna kitengo, 0–100 | Uwezo wa chanzo cha mwanga kurejesha rangi halisi ya kitu, Ra≥80 ni bora. | Inaathiri ukweli wa rangi, hutumika katika maeneo yenye mahitaji makubwa kama maduka makubwa, majumba ya sanaa, n.k. |

| Tofauti ya uvumilivu wa rangi (SDCM) | MacAdam Ellipse Steps, e.g., "5-step" | A quantitative metric for color consistency; a smaller step number indicates better color consistency. | Hakikisha rangi ya taa za kundi moja hazina tofauti. |

| Mdomo mkuu (Dominant Wavelength) | nm (nanomita), k.m. 620nm (nyekundu) | Thamani ya urefu wa wimbi inayolingana na rangi ya LED zenye rangi. | Huamua hue ya LED za rangi moja kama nyekundu, manjano, kijani, n.k. |

| Usambazaji wa Wigo (Spectral Distribution) | Mkunjo wa Urefu wa Mawimbi dhidi ya Ukubwa | Inaonyesha usambazaji wa ukubwa wa mwanga unaotolewa na LED katika urefu wa mawimbi tofauti. | Inaathiri ubora wa kuonyesha rangi na ubora wa rangi. |

II. Vigezo vya Umeme

| Istilahi | Ishara | Mafasiri ya Kawaida | Maagizo ya Ubunifu |

|---|---|---|---|

| Forward Voltage | Vf | The minimum voltage required to light up an LED, similar to a "starting threshold". | Voltage ya chanjo ya umeme inahitaji kuwa ≥ Vf, voltage inaongezeka wakati LED nyingi zimeunganishwa mfululizo. |

| Forward Current | If | Thamani ya mkondo inayofanya LED ionekane kwa kawaida. | Kwa kawaida hutumia udhibiti wa mkondo wa kudumu, mkondo huamua mwangaza na maisha ya huduma. |

| Maksimum ya mkondo wa msukumo (Pulse Current) | Ifp | Kilele cha mkondo kinachoweza kustahimili kwa muda mfupi, kinachotumika kwa udimuzi au umulika. | Pulse width and duty cycle must be strictly controlled to prevent overheating and damage. |

| Reverse Voltage | Vr | The maximum reverse voltage that an LED can withstand; exceeding this may cause breakdown. | The circuit must be protected against reverse connection or voltage surges. |

| Thermal Resistance | Rth (°C/W) | Upinzani wa joto kutoka kwenye chip hadi kwenye sehemu ya kuunganishia, thamani ya chini inaonyesha usambazaji bora wa joto. | Upinzani wa juu wa joto unahitaji muundo wa nguvu zaidi wa usambazaji wa joto, vinginevyo joto la kiungo litaongezeka. |

| ESD Immunity | V (HBM), k.m. 1000V | Uwezo wa kukabiliana na mshtuko wa umeme wa tuli, thamani ya juu zaidi inamaanisha uwezo mkubwa wa kuepusha uharibifu. | Antistatic measures must be implemented during production, especially for high-sensitivity LEDs. |

III. Thermal Management and Reliability

| Istilahi | Key Indicators | Mafasiri ya Kawaida | Athari |

|---|---|---|---|

| Junction Temperature | Tj (°C) | The actual operating temperature inside the LED chip. | For every 10°C reduction, the lifespan may double; excessively high temperatures cause lumen depreciation and color shift. |

| Kupungua kwa Mwanga (Lumen Depreciation) | L70 / L80 (saa) | Muda unaohitajika ili mwangaza upunguke hadi 70% au 80% ya thamani ya awali. | Kufafanua moja kwa moja "maisha ya huduma" ya LED. |

| Lumen Maintenance | % (e.g., 70%) | The percentage of remaining luminous flux after a period of use. | Characterizes the ability to maintain brightness after long-term use. |

| Color Shift | Δu′v′ or MacAdam Ellipse | Kiwango cha mabadiliko ya rangi wakati wa matumizi. | Inaathiri uthabiti wa rangi wa eneo la taa. |

| Uchakavu wa Joto (Thermal Aging) | Kupungua kwa Utendaji wa Nyenzo | Uharibifu wa nyenzo za ufungaji unaosababishwa na joto la juu kwa muda mrefu. | Inaweza kusababisha kupungua kwa mwangaza, mabadiliko ya rangi, au kushindwa kwa mzunguko wazi. |

Nne. Ufungaji na Nyenzo

| Istilahi | Aina za Kawaida | Mafasiri ya Kawaida | Sifa na Matumizi |

|---|---|---|---|

| Aina za Ufungaji | EMC, PPA, Ceramic | The housing material that protects the chip and provides optical and thermal interfaces. | EMC ina mzuri kwa upinzani wa joto na gharama nafuu; kauri ina usambazaji bora wa joto na maisha marefu. |

| Muundo wa Chip | Usakinishaji wa Kawaida, Usakinishaji wa Kichwa-chini (Flip Chip) | Chip electrode arrangement method. | Flip-chip offers better heat dissipation and higher luminous efficacy, suitable for high-power applications. |

| Phosphor coating | YAG, silicate, nitride | Coated on the blue LED chip, partially converted to yellow/red light, mixed to form white light. | Fosfori tofauti huathiri ufanisi wa mwanga, halijoto ya rangi na ubora wa kuonyesha rangi. |

| Lenzi/Usanifu wa Optics | Planar, microlens, total internal reflection | The optical structure on the package surface controls light distribution. | Determines the emission angle and light distribution curve. |

V. Quality Control and Binning

| Istilahi | Binning Content | Mafasiri ya Kawaida | Kusudi |

|---|---|---|---|

| Kikomo cha Flux ya Mwanga | Kificho kama 2G, 2H | Group by brightness level, each group has a minimum/maximum lumen value. | Ensure consistent brightness for products within the same batch. |

| Voltage binning | Codes such as 6W, 6X | Grouped by forward voltage range. | Facilitates driver power matching and improves system efficiency. |

| Color binning. | 5-step MacAdam ellipse | Group by color coordinates to ensure colors fall within an extremely small range. | Ensure color consistency and avoid color unevenness within the same luminaire. |

| Color temperature binning | 2700K, 3000K, etc. | Group by color temperature, each group has a corresponding coordinate range. | Meet the color temperature requirements of different scenarios. |

VI. Testing and Certification

| Istilahi | Kigezo/Uchunguzi | Mafasiri ya Kawaida | Maana |

|---|---|---|---|

| LM-80 | Lumen Maintenance Test | Long-term operation under constant temperature conditions, recording data on brightness attenuation. | Used to estimate LED lifespan (in conjunction with TM-21). |

| TM-21 | Standard for Life Projection | Projecting service life under actual operating conditions based on LM-80 data. | Providing scientific life prediction. |

| IESNA Standard | Illuminating Engineering Society Standard | Inashughuli njia za kupima za mwanga, umeme na joto. | Msingi unaokubalika na tasnia ya kupima. |

| RoHS / REACH | Eco-certification | Ensure the product does not contain hazardous substances (e.g., lead, mercury). | Masharti ya kuingia katika soko la kimataifa. |

| ENERGY STAR / DLC | Uthibitisho wa ufanisi wa nishati. | Uthibitishaji wa Ufanisi wa Nishati na Utendaji kwa Bidhaa za Taa. | Hutumiwa kwa kawaida katika miradi ya ununuzi wa serikali na ruzuku, kuimarisha ushindani wa soko. |